SAND WASHER

of the various problems created with the gulf oil spill/ one of the most lingering is the oil that will sink to the bottom and stay there for decades. That oil eliminates the possibility of sea life across a wide area of the gulf/ therefore it must be "washed out of the rocks and sand" if possible.

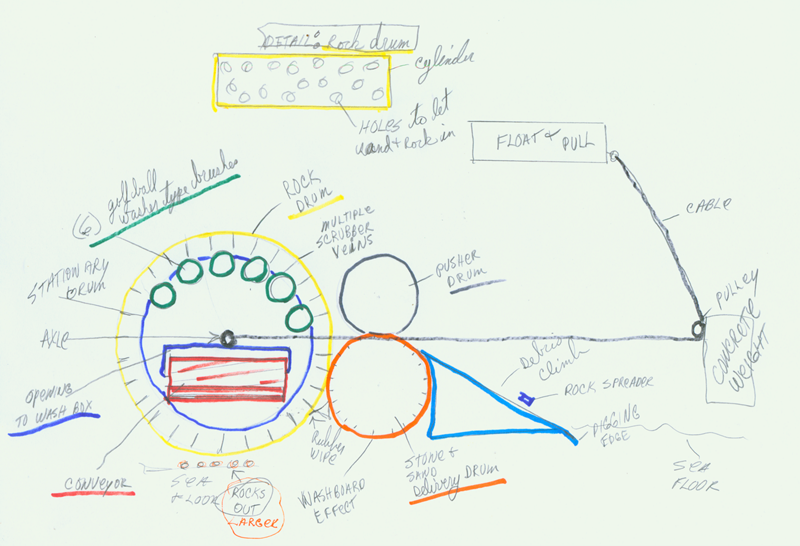

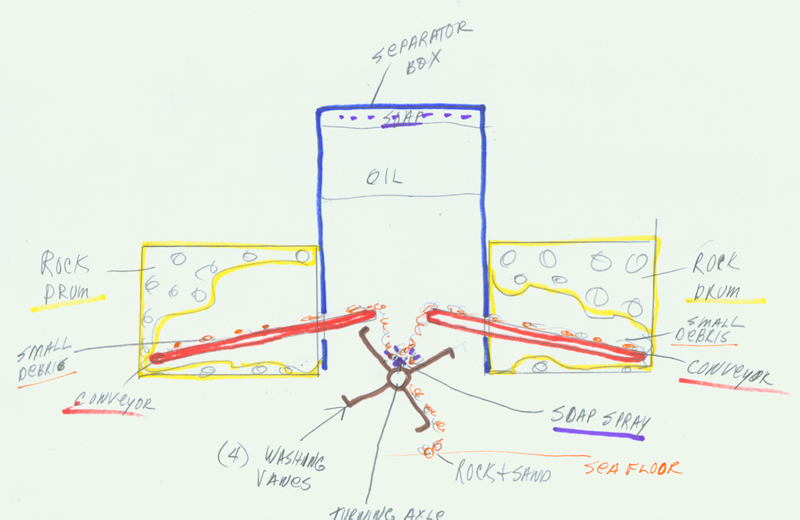

The machine described is for that specific purpose, and works in the following manner. What it does is: collect the top surface of the ocean bottom as if it were an agricultural tool on a farm. With its digging edge it lowers itself into the sea floor to scrape that top layer off. Forward momentum pushes it up the debris climb, and a rock spreader removes the "too large rocks" by pushing them to the side into a collection tray not shown/ or simply leaving them on the bottom by pushing off the side. The machine is shown with a cable attached at the most useful place, which is pulled along the sea floor by the cable, through a pulley anchored to a large movable weight/ BY the float and pull which gains its force for pulling by wave motion at sea level. A hose not shown that travels with the cable delivers oil to the float and pull from this machine, by density difference or other method. The machine works by guiding the debris or soil, up the debris climb where it encounters the stone and sand delivery drum, which is aided in its job to push sand and stone into the rock drum by a suitable surface. The pusher drum keeps various eddy currents from interfering and continues the spreading of debris in the most uniform distribution across the rock drum possible/ it may also contain a side "pin wheel" as a drive mechanism to help power the machine as it is pulled through the water (spring loaded) to account for variation in rock size/ it may need to be placed farther forward on the debris incline. The rock drum as is shown in the detail drawing, is riddled with a large number of holes sized for the kind of rock or sand being collected. What fails to fall into a hole, by escaping between the rock drum and the delivery drum is funneled in by the rubber wipe mechanism which acts to catch this. The rock drum turns, and as it turns the multiple scrubber vanes attached to this drum, pick up the rock and sand delivering it to the top of the machine by laying it on the stationary drum. Where it encounters the multiple brushes that will turn to accommodate the scrubbing action that is necessary to clean the oil off the materials. Oil and sand/ small rock will pass through the brushes contaminated with oil and fall onto the conveyor. A secondary means of cleaning the brushes inside the stationary drum is necessary (not shown). The inclined conveyor delivers the oil mixture through a side door opening to the wash box. Where this u-shaped container box contains two basic working parts: the washing vanes attached to an axle that turns. And a biodegradable soap spray incorporated into that axle which delivers the soap necessary for separating the oil and causing it to rise, within the individual area being washed. Four individual spray lines, which are energized by a simple slip ring pressure guide that releases chemicals in only one area. As the washing vanes rotate, the material moves and is dropped off by gravity onto the sea floor. It continues to rotate to repeat the process, small areas for maintaining control of the material help the rotation. More vanes work better. The washing vanes are perforated to allow flow, thereby aiding the soap. As the chemical mixture of soap and oil is lifted from the surface of the material it floats to the top of the separator/ wash box, where it is allowed to continue rising to the surface by a pre-mentioned hose, not shown.

The theory of operation is then simply. The machine digs the sea floor, maintaining a critical depth with common gauge wheels or glides, not shown. That sea floor debris is raised onto the delivery drum for distribution across the rock drum. It enters the rock drum though various sized perforations in the drum, and once inside, the scrubber vanes carry the debris up onto and around the drum. Taking it over the top of rotating brushes or whatever you like, which clean the materials/ allowing the sand and soft materials to be lowered inside the stationary drum which are expected to contain the majority of oil, onto the conveyor. The larger materials having been washed continue on down to the bottom of the rock drum where gravity takes them back out of the holes that were used for them to enter it. The conveyor delivers the worst of oil and sand mix into the wash/ separator box; and dumps that material onto a rotating vane system, which uses soap in one form or another to loosen the oil and cause it to rise. At the top of the wash box is an outlet, that provides oil the possibility to rise and be contained within the float and pull for pick up later. Primary pulling power is associated with wave action on the ocean surface. Various drive mechanisms can be used to power the moving parts, if wave motion is not considered enough; it was not deemed necessary to provide them. A moveable anchor provides direction a ship changes its position. A gps monitor on board the float and pull tells the shore when it is time to move the anchor. Some type of conveyor may be necessary to move the sea floor onto the delivery drum instead of simply a slide.

All machines and writings provided by me on this site are free, use them as best you can.

As to other developments: opportunity to see a visual picture of the smaller leak provides the simple statement: WHY can you not shove something into this pipe, it is completely half open and will accept any manipulated substance that is guided into place. Such as a sealed rubber bladder, which can then be inflated by a variety of chemical compounds that will permanently expand to inflate it. Permanently sealing the hole/ it is not high pressure/ like an inner tube, shoved in the hole with foam inside for simple expression. A variety of methods will work, including a simple pipe clamp sized to the hole for installation over it by scissors action or "vice grip" means/ if it does not then leak other places. Or simply pumping in concrete and rubber or other methods known to plug such a leak. No excuse. Do note, THIS PICTURE being shown is NOT the big leak/ and does not constitute the major loss (wouldn't want to scarce you)/ or YOU just plain don't need to know! As to the large leak on the blowout preventer, again a steel tank can be used/ and the statement "the preventer is set into concrete" means that with some planning a flange on the bottom of the tank with appropriate materials for sealing it inside, gives you the opportunity to "nail it down" INTO that concrete. If the pressures are believed to be too great for sustained capping/ a relief line to the surface can be incorporated and sustained, if planned for at the beginning.

A footnote, the use of flotation devices every hundred feet or so along the pipe: to lift and hold the surface delivery pipe to be installed; will significantly help stabilize the entire operation. A door allowing entry into the tent or teepee at the bottom will allow more specific funneling later, if you can work the submarines well enough.

The shore line, or more specifically marshes can be protected more efficiently IF you cut a trench in front of them, specifically if you aid that trench with "a suitable snow-fence (easy to get, for turbulence as in the effect of snow falling due to the fence) or similar". Set whatever machine you have on a float platform and continue working/ the dug materials on the back side/ fence in front at a distance chosen such as is done for snow. The heavier oils will tend to fall into the trench, making it much easier to recover/ the lighter oils can be burned prior to hitting shore.

The effort to protect the shore can be aided by "the floating bobber effect". A simple machine that consists of three basic parts. Wave effects will agitate this floating barrel, it is designed with the top edge to be slightly above the water level/ for the purpose of waves overlapping it/ but not submerging it. Inside the barrel is a series of screens which the water/ oil mixture lands on. The screening holds onto the oil, the water will lower itself to the bottom of the barrel. A pump that is operated by wave action (either like a hand pump or a simple turning wheel) continually pumps the water out, leaving the oil behind. It will require hose hookups, that gather oil from several barrels to a waiting container, either floating or on land. To aid in the separation of oil and water in the bottom of the barrel as solids will gather there/ common oil filters at the bottom of the barrel will aid in keeping the "thick stuff" out/ while allowing the water to pass through. Lighter materials stay at the top, therefore oil collection is done mid barrel. A float shutoff stops the pumping mechanism from lifting the barrel out of the sea. These are tied in a line, and anchored to whatever is available or taken to the site. Additional recovery is applied by a system that uses a suitable material along the shoreline floor/ to gather the oil solids, and then drag them to a cleaner. The device shown here intended for deeper water can be rearranged to follow the sheeting material along the coast instead of hauling it up and down. Simply anchor in the sheeting and let the machine come to it. Small protrusions in the material sheeting "like plants", will aid in collecting oil. To keep folding of the material to a minimum it is necessary to use slats in that material {properly placed they become like links in a chain for hauling in the materials}, and a guide to turn or smooth the material as it heads into the machine. A motor will do the work, but the obvious alterations should not need another picture. An alteration in the oil well plug designed for land use, is simply to clamp the machine to the blowout preventer ( like grabbing it with both arms) so that it is clearly solid and can use force. When ABSOLUTELY certain you are prepared. Then cut the pipe off the top and set the plug in place. Hydraulics do the work/ hydraulics deform the plug to make it fit the hole. Be certain, nothing can go wrong with the lines that operate the device.

As to fools and idiots that refuse to get out of the way/ and let you work: take them to court/ but maintain no possibility exists that you will not defend your future and your joint property against those who have invaded everything regarding work and livelihoods. Demand your leaders fight with you/ NOT against the oil industry: BUT WITH ABSOLUTELY CERTAINTY, they must side with the people and the alternate industries which oil has damaged so severely already. Or in other words compete to shut off this oil now/ before it is too late to matter. They had their chance! With a camera, a microphone, and two fishing vessels, a "tent/ teepee" can be lowered into place. A hose attached to it will work if you allow the water to maintain pressure variants inside and out. Once in place, pump out the water, and it will bring the oil to the surface with it. Where current does not exist, what is set on the bottom of the sea will remain in place. When proven anchors will be placed. It's a choice, wait for the expert, who has been proven to fail/ or do the best you can. NOT A FIGHT/ but a clear, work with us, and do it our way now. OR we will demand from OUR GOVERNMENT/ OUR NATION/ AND OUR LAW: absolutely everything you (whosoever bears any responsibility) own/ and not take one penny less. No hiding in corporation or appeal; personal liability holds against all who "took my livelihood and future, because you gambled or failed to be certain this could not or would not happen/ therefore I take yours". BOTH OF US, paying with work or money (life & time & resources) for the rebuilding of environment; until it is clear: both of us, may now go our own ways. This matter changes from an accident/ to a reality of choice: when every measure that can be significantly tried, fails because of greed, "failed and foolish expertise", or just too damn much pride or misunderstanding: therefore learn, ITS SERIOUS FOR YOU TOO! Just tell em plain: we got news for you; "you ain't god". And there is no place to hide.

As to the public, the idiocy that believes oil is a god to you; the absolute failure "but I want to drive from my door to the end of the sidewalk, a thousand times a day" WILL CHANGE, when they learn the loss of this food supply WILL affect them for years. Starvation begins. This nation grew in population more than double in the last forty years. This world doubled in population, adding more than 3,000,000,000 people in the last eighty years/ and that number rises faster with every week. Food and water are life and death/ oil, is an excuse to be selfish, more than it is a need.

Should the new “top hat” method of oil siphoning fail completely; as the problems are numerous. The critical question is not “what is the oil company” going to do now/ BUT WHAT are the people themselves going to do now. The answer is: “its our turn to try”. Let those who have a solution or device prepared “get in line”/ the first to contain the spill gets the money; all who built a critical tool that could be considered to potentially work, shall have their expenses covered. In terms of lowering a “teepee”/ don’t forget the necessary step of pumping water out of the hose to accommodate the oil initially: and sized to allow natural rise of the oil, during normal operation (without a pump), with a valve at the top for adjusting flow to least water rise along with the oil. That hose must be attached prior to lowering/ open during lowering/ and of sufficient tension to remain open during the pressure difference that will occur between the oil inside of it/ and the water outside of it. If you attempt to plug the line with the tool described in “oil spill”/ don’t forget, it is necessary to insure completion of the job, by such things as secondary saws, or plugs/ that can be rotated or lowered to finish if something goes wrong (because you are opening the pipe: try it out at a less vulnerable spot, with similar characteristics) . A second machine should stand at the ready in case something fails with the first/ an alternate saw or means to let go of the “useless pipe” might be advisable, should a great deal of tension erupt onto the plugging device itself. The critical solution to who must pay remains the same/ however the critical truth of an invasion of our lives, an attack on our homes, a disgrace to our nation demands: WE ARE, now in charge/ and will send you the bill. By taking control over any and all assets as needed. There will be no containment, should a hurricane come. The pipe and funnel (top hat) are arranged to be essentially a wrecking bar (crowbar)/ with extreme leverage working against the blowout preventer, as the pipe “moves in the sea”; and wears against whatever is rubbed. The question over time is: WHAT will break first/ and that had better be “the top hat”, because anything else will be worse. Even if it works to some degree, it is absolutely necessary to be prepared for an alternate solution when it fails. In no way is this a long term solution, or the means for critical containment. Demand pictures, and verify the truth. Use whatever helps, but do not accept less than what is needed for life.

The tragedy is about to increase in scope and size: any assumption that opening the entire well by removing the blowout preventer/ or in any other way preparing to gamble on shoving another pipe over the existing well, with absolutely no means of controlling the flow should it fail. Is insane. The critical truth is very simple: LIKE TRYING TO ATTACH A GARDEN HOSE TO YOUR FAUCET (running between 30-60 pounds of pressure) WHILE IT IS RUNNING/ so is the reality of trying to place another pipe over a gushing well at thousands of pound of pressure. Even if it can be done at the surface/ it cannot be done at 5000 feet in the sea. A remote controlled submarine CANNOT HOLD THE PIPE IN PLACE: the only possibility of doing that is to lower large weights with remote controlled winches to move the pipe around. Added to that, even if they managed to get the pipe on top of the other gushing well: THEY CANNOT SEAL IT/ THEY CANNOT ANCHOR IT IN PLACE (WHICH MEANS, it may or may not stay on top of the oil)/ and they cannot fix the situation for ANY TYPE of long term solution! Neither can they shut this off, by that method: any restriction in the line, and the oil will flow out of the bottom of your pipe. Because they cannot attach them in any substantial way/ unless they can drill down around the well casing; which leads to a loose pipe that will not be sealed. Neither can they drive it down/ because a 5000 foot long pipe will not accept that method of action against it. The only 2 possibilities are weights slid down the pipe/ but they must hit an installed collar to accept that impact/ and the weights must then fall off by themselves, so that the next impact can occur; or there will be excess weights causing stress on the pipe (the pipe is small in comparison)/ and limiting the effect of each successive blow. The other is to place the pipe over it and intentionally seal the top so that pressure pushes out the bottom and removes the sea bed as you go down with that pressure forming the way. IT WOULD, take a substantial amount of drilling by this method to have any effect, and it is unlikely ever to seal. It is possible if prepared in advance, to make a mechanical device that could help. Or it is possible a prepared taper collar could be driven down around the pipe once in place and weighted to keep it there after it is placed. NOT a good plan, unless you wreck the containment you already have, and if you do wreck the blowout preventer/ then you will be left with a well casing pipe that is neither round or suitably straight upon which to place a pipe. If you wreck it/ the most logical method is to plug it with a deformable “torpedo/ cone shaped” plug that is inserted into the pipe and hydraulically reshaped to fit its area. THIS requires a machine that is already formed and ready to go, which can be manipulated to do its job, from the surface: BEFORE you gamble with the preventer. STOP worshiping the oil/ money. STOP THE LEAK, or contain it safely as possible.

Additionally the intent to lower a smaller concrete box on top of the blowout preventer will fail badly/ because again, they may accidentally destroy the blowout preventer, thereby opening the hole, when you have absolutely nothing else prepared to help the situation. Lowering a small box over a protrusion with lots of things sticking out from it: IS NOT a safe mechanism. It is gambling, with major consequences for failure. Further by making it out of concrete, you lose the effect of heat transfer thereby increasing the potential of ice forming inside. THE ONLY THING NECESSARY in this situation is: a membrane which will separate the ocean from the spilling oil. The oil is under pressure, and will rise: THAT MEANS, all it takes is something like a tent to gather the oil into an area which then gives it rise to the surface. See below.

The media does NOT like me/ efforts to contact others have been blocked: ITS YOUR JOB.

THE ICE FORMING

The critical element here is NOT the ice forming, but what can you do with it. Therein we understand, that ice forms a barrier and seal that is hard to defeat. Consequently “IT COULD BE, a good thing”. The question is: if it will seal the container and shut the flow of oil off simply by weighting it down/ then why did that not get done? The question of greed arises: want to get that damn oil/ DON’T want it sealed?

The fundamental question is how best to use, or work with the ice follows.

The issues of a concrete structure raising above where it is installed are mute/ because with weights or anchors placed; that concrete structure can be held in place. NOT the issue. Instead there are two distinct questions: HOW BEST, to direct the flow of oil and gas so that it seals the area below / and how best to keep the ice from melting, in a sea that is hotter than ice can be sustained at, unless it is continually reinforced with cold.

The functional reality is a change: to accommodate the need to build ice/ the internal components of the box MUST remain as it is. The pressures that exist at the flow source will provide a simple “water wheel design/ powered by that pressure” with the force necessary to pump what it collects down in an effort to direct the ice buildup below the current level/ and leave the top open. IF YOU CAN SIMPLY WEIGHT THE STRUCTURE DOWN AND KEEP IT SEALED: DON’T do more. But that is highly unlikely as ice will melt. Therefore it is necessary to use consider more. More means that you will pump the gas down/ by choosing to build a pump that is capable of separating the three components at work. Density, volatility, and pressure dictates: water is at the bottom/ oil in the middle/ gas on top.

First the pump itself: is a horizontal “old fashioned” windmill version with many blades rather than a turbine flow pump with singular or minimal area’s that can become plugged. Second is a rebuild of the concrete structure, by creating a manifold on top of the structure either cutting the cap off of it/ or drilling holes in it: to place multiple tubes that will be used as heat exchanger’s / that then join back at the top to create a hose fitting to the surface. That heat exchanger will remove the cold to ocean temperatures/ therefore calculate how much is needed; and what you can do quickly. Holes drilled in the concrete lid/ flanged pipes shoved through from the bottom and epoxied in place/ welded to join, with structure to establish critical hose control.

Next is a recognition of volume/ wherein the pressures created and released are necessary only to create a seal of ice at the bottom if possible ( a small amount of energy)/ the rest being capable of use for “electric, or mechanical heat”. Which means either electric heating elements or competing mechanical “windmills” to generate friction heat, or both. This keeps the ice from forming.

Third is the pump itself: contained as in the separation of oil into its own different participants/ as is done in the making of gas. Proves that gas goes on top/ oil in the middle/ heavier materials at the bottom. Heat proves useful in limited separating, where this is as simple as BASIC “gas/ oil/ or water”. The probable arrangement most conducive to helping in this situation is a container rising above the top of the concrete structure out of its center funnel; surrounded by heat exchanger’s/ and fitted with electric heating elements. Wherein the oil collects and is contained by doomed area’s which reduce the flow by orifices that slow it down. Oil comes in and collects under pressure/ less dense materials rise to the top/ multiple orifices sized to create and control the pressure from one side to the other, force more and more gas/ oil/ and water to separate as it rises in the chamber. Simply by allowing the mechanics of subtle differences in chemistry to work.

Three hoses are necessary to go to surface. One collects at the top of the separator chamber for gas/ one collects oil from the side of the collector and forces or allows that oil to be pushed back between collector plates/ to return to the bottom of the collector/ and then rise within pipes inside the collector to help warm the solution/ going through the top of the separation chamber to the surface. One collects the oil rising from the heat manifold that rises from the top of the concrete structure for its hose to the surface. A collector plate recognizes: when pressures emit from an orifice, there is a spray that occurs. That spray creates a turbulence that will generate more gas separation/ therefore it is useful to create the next stage gas release at a higher position than an alternate orifice lower on a collector plate funnel. The design incorporates a funneling effect.

The theory of operation is then: the use of pressures already in evidence will provide the means of energy to pump or heat the medium of oil water and gas. The use of a design to slow and collect a greater percentage of oil and gas at the middle of the concrete structure/ will allow a moderate separation of the two, by simply incorporating the different physical properties between the elements involved.

The list of people responsible grows to those who build ocean platforms for drilling/ those who make the equipment used/ and those who use the end product such as gasoline, heating gas, etc. ANY significant suspicion: that the environmental damage is secondary to money, MEANS: any and all revenue, is turned over to the people themselves/ as a means of payment for cleanup of the environment; an accident is different than intentional “money first”. The pension plans & salaries of all significant leaders, as their proven failures cost us all. That continues to the tankers that deliver oil/ the countries that sell it as well. NO MORE ESCAPE, you sell it, or you buy it/ then you are responsible. Oil loss is a world crisis created by the demand of human beings across this earth. YOU caused it/ YOU PAY. We have only one earth, only one chain of life to keep us alive, without food only war and cannibalism is left. As is evidence and obvious across this world, “your money” is a fantasy, and a failure. “The fantasy of a GREEDY FOOL IS: with money, everything is possible, FOR ME”! THE REALITY OF EVERY WORKER IS: that money is a demand against me, against every resource I need to survive: my life. As a society it enslaves us/ by presenting only one, or a tiny few: with everything. “That ain’t democracy”! The difference between “I, or EVERYONE”/ needs no real explanation.

IT IS UNWISE to use dispersants on this oil/ because even though it has consequences on the surface. The reality of FAR MORE LONG TERM consequences grows as it rests on the bottom of the sea floor. Without that environment, no creatures will exist there. TRY TO COLLECT IT instead/ rather than hide it: AS BEST YOU CAN, and hurry (anything that works). Methanol is just another pollution, that will escape into the sea/ IT IS WRONG to use it here. Particularly when the ice problem is as simple as using the heat already in the ocean.

Set the tent version, (as written below); of collector in place. Prior to finishing this project, as it is simple: tents are available, and will work. If ice is a significant problem/ it just needs a higher teepee style tent; such as 100 feet at its peak/ with an aluminum skin to exchange heat better; with numerous small one way valves in both directions that are spring loaded for a specific pressure to protect the tent. Better, is for later.

Lowering the concrete structure

the sea is blackened where the oil is spilling, making it impossible to know where to lower the concrete structure unless there is some realistic type of sonar device that will locate and pinpoint the hole. Although it is without doubt the flow is massive, in absolute darkness/ a tremendous weight can do more harm than good. Making a horrific situation even worse/ unless it is already as bad as it could get.

An output beacon placed by sub on the leak itself a receptor inside the concrete chamber to hear that noise: the chamber itself will help focus on that noise. Alternate noise levels placed elsewhere for positioning. The sound of the leak itself is probably enough IF YOU HAVE A RECEIVER OR MICROPHONE for listening inside the chamber BEFORE IT GOES DOWN. So you can position the chamber! Or inside the hose connection that will be made, so a line to the surface can exist simply. That hose should exist prior to lowering so that relief can exist immediately or if not even a small hole around the bottom will not only be excessive and impossible to fix without some type of arrangement inside the chamber. Such as a guillotine knife to slice the pipe or clinch it down/ some type of deformable cushion that can be inflated and caught by flow to then wedge itself, into the crevice to stop the flow. Something! Or some type of arrangement around the leak thereby identifying its exact position. Or some type of tenting around the concrete structure that widens like a funnel, thereby acting to help clear the water when the valve and hose arrangement is opened to the surface, while the concrete structure is hovering overhead; making it potentially possible to see what you are doing. Or at least directs the oil up and through the concrete so that some idea of this is the right place exists. The tent simply folds away, the material simply tears. Or in other words; light and crush-able. Unless you have the concrete structure full of air and completely held by crane, no clearing will occur/ if you do, it is a limited reprieve unless you are prepared to pump enough air back down the hose to do it again. Or a big enough pump hooked at the surface to simply move the water and oil to the surface so that you can see the concentration level coming out, thereby again having some direct type of reference to this is the proper place / have a barge ready, its mostly oil. If you get it adjusted correctly oil pressure will find its way upward/ which means a tent affair, even out of light materials so long as the tube is big enough to limit pressure inside the tent is enough. Four tent “pyramid shaped iron members”, with tent materials to create the funnel ending with a hole at the apex for hose relief, is an alternate method. Just lowering a weight into the water hoping, is not enough. The concrete weight is intended to hold the pressures down/ but if you are removing enough pressure to balance the oil and direct it into the funnel; the pyramid structure defined above will work just as well; so long as you can keep the hose from moving substantially. “Think big tent”. Think about how to use the tent and hose to direct the concrete structure down on top of it; if necessary; sounding devices/ laser devices/ something. Which if you are planning to do that would require a flexible hose, and a cable hooked to a tent leg/ so that when the concrete dome went down you could simply pull the hose aside drop down on the tent, and crush the old hose instead of disconnecting it. the tent needs some type of tensioning device to register when the balance between suction and pressure is acceptable. Perhaps even a relief valve of some type, which could be as simple as a seam which pulls apart under pressure, and then is pulled back by springs. Remember to be able to re-hook if necessary; on either device: that would necessitate some type of float and line that could be released remotely to bring up the heavier line; something. If you put the tent down first, it will allow you to prepare everything necessary for lowering the concrete structure as a more permanent fix. Or at least potentially see what the situation is, more clearly after a few hours time: by adding sensors within the tent prior to lowering it/ wires up the hose.

In terms of dealing with the other massive leak, the use of a large tent itself, in the shape of a pyramid or teepee allows the opportunity to direct the oil to the apex hole where it is immediately hosed to the barge on top of the ocean. Immediate relief allows for minimal material, as it is then just acting as a separation layer between water and oil. No “great weight” needed, so long as you continue removing the oil. Plenty of tents already made just change the top, to apply a hose, or two. Where debris makes covering nearly impossible/ again the use of a large ship at speed is a tremendous source of energy; like pulling a truck with a stretch strap once you get attached, there is plenty of energy available to move the debris: but DO use a warship of some kind because the weight applied to the rear of the pulling ship WILL require a very heavy hull. Otherwise the use of a tent that folds out like an umbrella will give you the opportunity to thread the supports through as best you can. The tent material itself; can then to dropped from the top/ cut as required and with surplus material re-seamed IF you have prepared the material with suitable guides to cut between and a rope or cable or velcro or something to not only pull it back together around the obstruction, but hold it in place as well. Some type of air bag or something, with a weight to counter act the air/ or an air bag that will extend from the support taking up that space. Or a spring loaded bag that will move across the opening with material if released. Or multiple layers inside the tent which act like individual guides, tied to the tent structure on a horizontal spring arm, which will deflect and return to position directing oil to the funnel above. The flow itself will direct most oil, if you simply keep the material out of the way. The flow will rise up the tent material into the seamless dome if its done correctly; openings at the top of each individual flap so the oil that goes between layers can get out into the tent dome. The support arms that define the tent itself, need not be anchored unless there is current. However to move the structure on the sea floor surface, some type of hook up is necessary. An anchor and a cable if you have the structure so rigged and it moves. Inside the tent a flexible joint at the apex for primary oil and an extendable small funnel tied to the supports with winches that must work together for movement around on the inside of the tent: can be used to funnel more oil than water into this main line. At least three winches with one winch to extend or contract the adjoining pipe between the apex and actual funnel for concentrated oil. Strain gauges if nothing else to determine if the winches are ok. Check the oil stream to identify where to direct. A secondary mixed oil line is incorporated at the apex of the tent to establish another hose going up to surface which is then used to fill an alternate barge with less concentrated oil. This tent dome NEEDS a big enough hose at the top/ or it needs the correctly sized pump that cannot be stopped, or the tent inflates and is destroyed. Too much pump and the tent deflates and is destroyed/ therefore a variable opening or a properly sized pipe is necessary. Strain gauges on the bottom of tent structure frames can weight the effects. Or just abandon this separation in favor of time saved. Most oil/ water is pumped into an abandoned oil well for time separation, and later removal.

IF they do break off the well head, leaving it impossible to re-hook or remove or use their concrete dome. Or the dome cannot be removed, because it is partially working/ a tent over the top will have to do; with some type of adaption to let the surface delivery hose be included, and then tightened around that hose when in place. Thread the hose through the tent material prior to lowering if you can, with simple lacing to draw it up. A second method is if flexible to pull the hose down to the sea floor so it need not interfere with the collection dome in the tent. If it is a tent, the flexible sides would allow entry at a later date/ on the sea floor to attempt repairs. Adding sufficient pumping volume increases visibility inside the tent so long as you don’t collapse or tear the structure. If the well casing is open and exposed a torpedo style plug can be inserted, and deformed from the inside to plug the hole. If the pressure is enormous that plug would contain an escape valve for pressure reduction and later closure after the plug is made. Anchor points in the sea floor allow plugging to go forward. If necessary, a smaller steel dome with working valve and drilling anchors to establish hold on the sea floor can be used.

More at www.justtalking3.info

The function and foundation of elemental truth found in this gulf oil spill is very simply based upon two fundamentals: that it could have happened to any oil company/ even though a greater risk exists with depth, it is not the depth that caused the initial problem. THEREFORE any company, etc that is operating in ocean waters, or any water in this USA bears an equal responsibility to the costs and consequences of this disaster. NONE were prepared/ therefore ALL are equally responsible; as is the US government, homeland security, fema, coast guard, and military who were also equally unprepared. No help has been found at the university either/ but that is a separate issue, resulting from their immersion in fantasy, and a complete denial of reality; or they would have been prepared. More simply every phase of leadership FAILED COMPLETELY.

The second fundamental is: that although we the people did not have any control over this failure, how few cared/ how few still believe the worst failure here is the loss of oil, so their price for gas will go up/ how few are honest enough in their heart, to understand: this crisis is more, than you can even conceive of, if not soon contained. Once again, IT DOES NOT MATTER, whose fault it is at this moment in time. What DOES MATTER IS: everyone must do the best they can to help alleviate the worst that can happen. Everyone from the garage mechanic to the university to the military MUST do whatever they can to save our environment and the process or chains that must exist to protect life and your own food supply. Not important? The world grows at 2 million more mouths to feed each week/ 7 billion of us, each wanting to be fed; and this oil spill is about to permanently take away MILLIONS OF TONS OF FOOD. Stop worrying about the insanity of money/ and start understanding: the edge between life and death for this planet is severely close, work or die.

As to money, so that you can work and survive: the first part of the process is, to encourage more workers, you will look to the "experts" who are cleaning up the oil today. With your own experts you will establish exactly how much oil they bring back "cleaned from the ocean", and demand the same level of pay per gallon of actual oil brought to shore, as they get. Let none say no. If you cannot collect oil/ you can organize and protest and do whatever you can do to insure, those who honestly help SHALL be paid.

My own work is limited to the ideas found below for assisting you in this work/ all are free, nothing is restricted or owned, "its yours"; do with them as you wish. YOUR JOB, is to use the information as best you can/ regardless who you are: and find a way to help this earth survive. IT IS, "up to you"/ not me. Fail to care, and the slide into hell will increase.

The SPINNING SEPARATOR

the critical question in separating oil from water is: what are the differences that can be used to redefine the solution into its composite parts? That primary difference is: solubility, density, and viscosity. Oil does not mix well with water/ and it clings harder to most surfaces than does water. Given that it can be conceived given a continuous, but realistic flow of water into a dedicated sorting bowl. That by slowly spinning the solution of oil and water what is less dense will be thrown farther at a slow spin. Or more simply work its way toward the outside edge of the bowl and cling to that surface. This separates the oil and water/ and then by using a wiper blade on the sorting bowl surface, that oil will be forced to rise, and as it does it will go over the edge into an oil reservoir/ which is then gathered and pumped into a trailing barge. As the oil is taken out, and the water finds its way to the center of the sorting bowl, a pump is used to suck water out through the structure stem, that supports the wiper assembly. Draining it into the ocean on the side of the assembly. A front extendable nose is used to gather and force the correct depth of water into the assembly/ requires sides to contain the mixture until over the riser. Forward momentum is simply used to force the oil and water mix over the ocean riser. Which then is separated out into the various sorting bowls that will be incorporated as one assembly either going through the water/ or stationary, with water pumped onto it.

WHEEL SEPARATOR

This machine separates oil by the process of adhesion between the oil and the spinning wheel materials expected to be an steel mesh screening. In three separate designs on the same wheel/ or turning axis. Whatever works best. As the wheel spins: "likely best in an opposite direction to water flow". The screening is submerged into the water thereby picking up oil. As it rotates around in a continuous circle, the oil is raised up and under the centrifugal fan which forces air through the screening thereby removing the oil/ water is separated out as it turns up and above the ocean surface; thereby an appropriate sized wheel. The oil "rains down" due to air flow into the oil reservoir nestled within the rotating screen wheels/ and intersects the axle with seals and bearing surfaces/ to dump oil from the reservoir into the axle tube delivery system which then transfers oil into the tanks on either side. A weight not shown is used to hold the reservoir in the upright position, hanging like a pendulum on the rotating axle shaft. It is pulled through the water. Small horizontal vanes inside and outside the screening wheels/ on the screening, may help significantly, to haul a greater load of oil to the top.

Wave separator

this machine is composed of two or more pontoon float tanks for buoyancy and containment of collected oil. In-between these tanks are an assembly of wave slants which simply pick up water by forward motion of the pulling vessel. The water is held or compacted on these wave slants causing the oil to rise due to density. As it does rise above the water, as is determined by the force being applied by the ship/ it goes over the top of the wave slant and into the gutter, which delivers it into the pontoon tanks on either side. Multiple units assembled together. A pull behind barge or hose going forward to the vessel removes the oil.