WELL SHUT OFF/ UNDER SEA

(Wave seal)

this is a method to turn off the oil leak, from the broken pipe under ocean in the gulf.

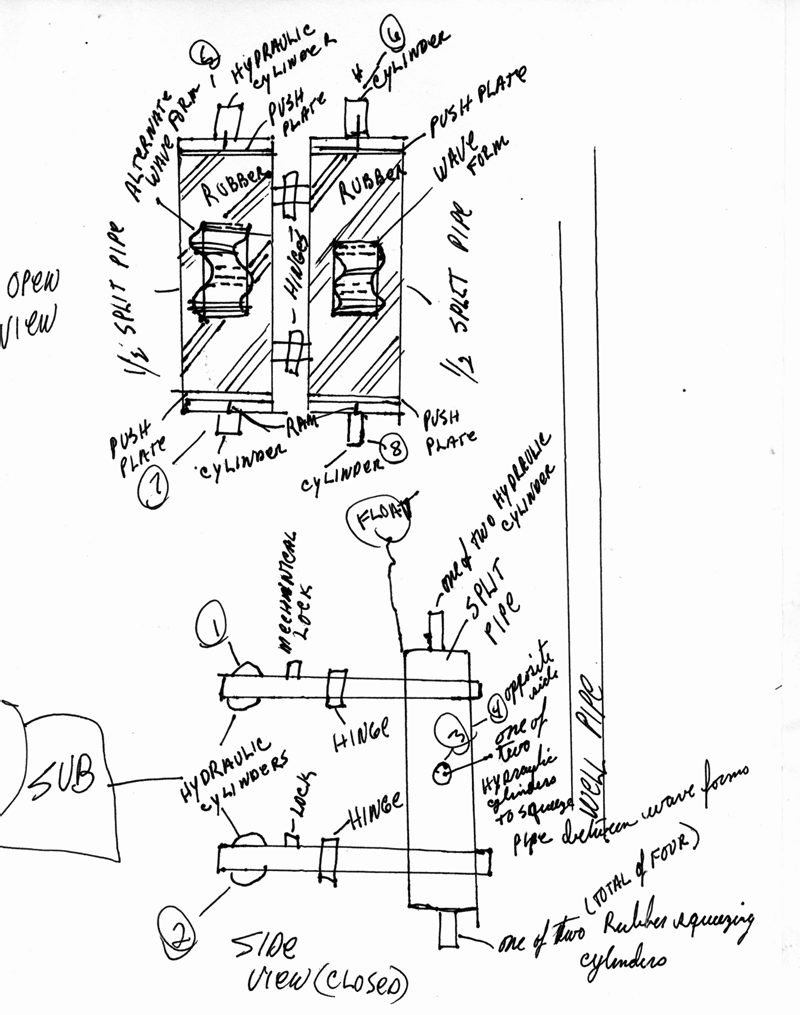

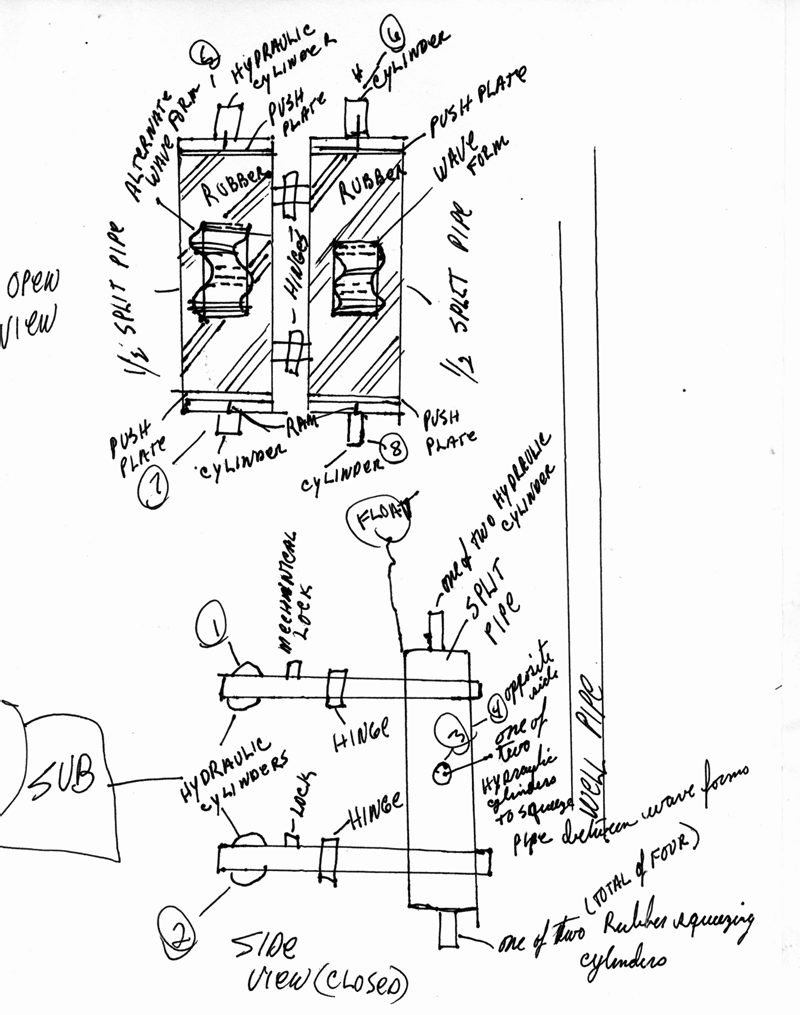

The method is to attach the mechanism to a submarine, choose a spot above the sea floor with at least one additional method of “trying again”. And clamp the split pipe valve onto a good section of the pipe by operating the hydraulic cylinders 1 & 2 at the back of the hinge assembly. Like a scissors hinge, the split pipe is used, to surround the well pipe and then shuts using mechanical locks to insure it remains in place.

Once in place and locked the hydraulic cylinders 3 & 4 are used to crush the well pipe in-between the wave forms identified in the open view (a ramped area prior to the crushing area, would be good): but they are designed to allow the rubber, or whatever material is used to conform without sharp edges or more simply to grant the best seal possible/ such as a half moon shape. They simply collapse the pipe by a method of pushing the walls together to form a seal. It is important to identify exactly what version of edge or wave will work the best on the pipe to be crushed. As a final measure of containment cylinders 5-8 are used to crush the rubber insert that fills the split pipe to contain any problem with the well pipe rupturing at the wave seal. It is also possible to simply pump in a sealing solution of some sort once the main device is locked into place. Obvious structural requirements and seals shall be used. The sub attaches with breakaway fittings, or the wave seal is self contained. Obvious electric/mechanical motors can be used in place of hydraulics. The wave seal should be fitted with anchor lines, so that the well pipe cannot be stressed unduly/ once the line is sealed the rest of the pipe is cut away; a common insert plug with useful motor drive to expand the rubber would aid the seal. The float counterbalances the weight to allow sub operations to be nearly normal under slow conditions.

After sealing; IN THE FUTURE/ the addition of a tap by similar methods can be used. Methods for oil collection are suggested.

Let anyone who makes the device and proves it works: be provided with the money of making it/ its free from me. In other words GET IT DONE NOW/ don’t need no damn engineering degree: we need the seal now. No shit head excuses. Remember it has to be operated from a sub/ which means the more self contained; the greater the opening for guiding it onto the pipe (such as “antenna guides”)/ the simpler the process for finishing the job such as “push one switch”: the more likely it is to be useful and make you money.

In the event that the drilling rig has made it impossible to use the above clamp and seal. The next step is to determine how best to lift the machine off the blow out preventer. That is done by lifting the anchors and their cables/ attaching those cables to cranes or military boats that will then use their motors to pull the drilling rig away from the area required to seal the pipe. Add more cable if necessary/ make a decision about the direction and go.

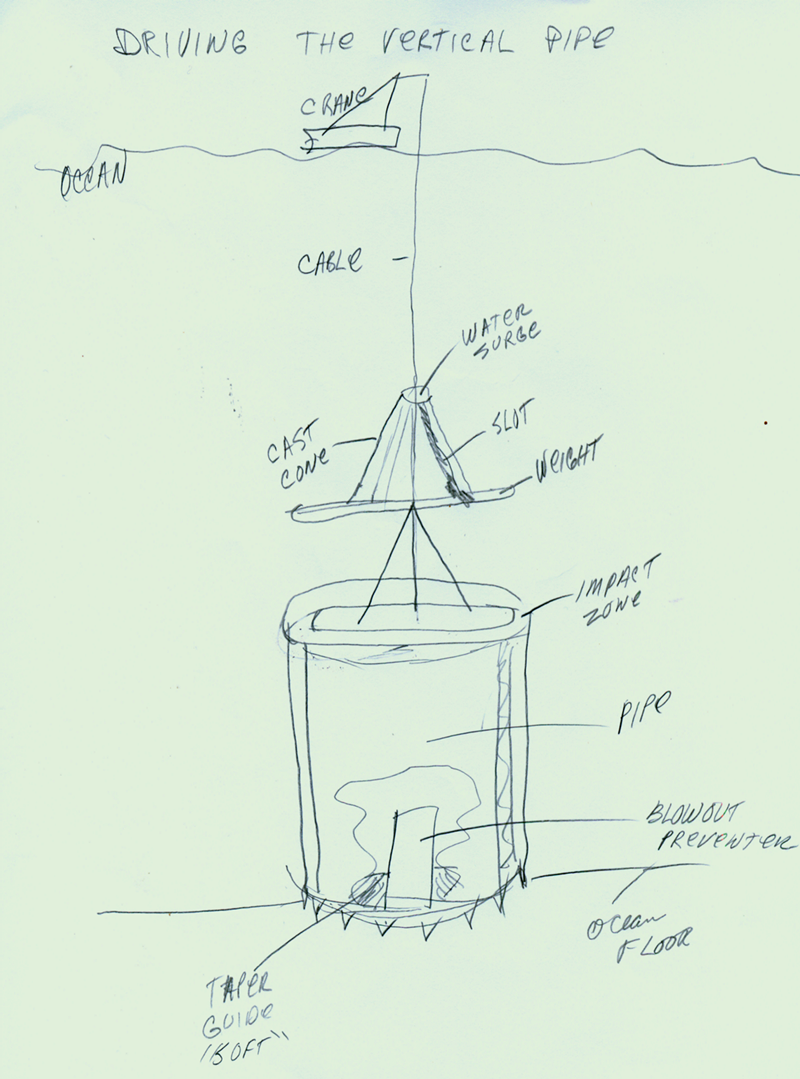

Access over the preventer means, in all probability that the well pipe is ripped from its anchor in the preventer. That means only one of two options remain. Either an enclosed pipe,

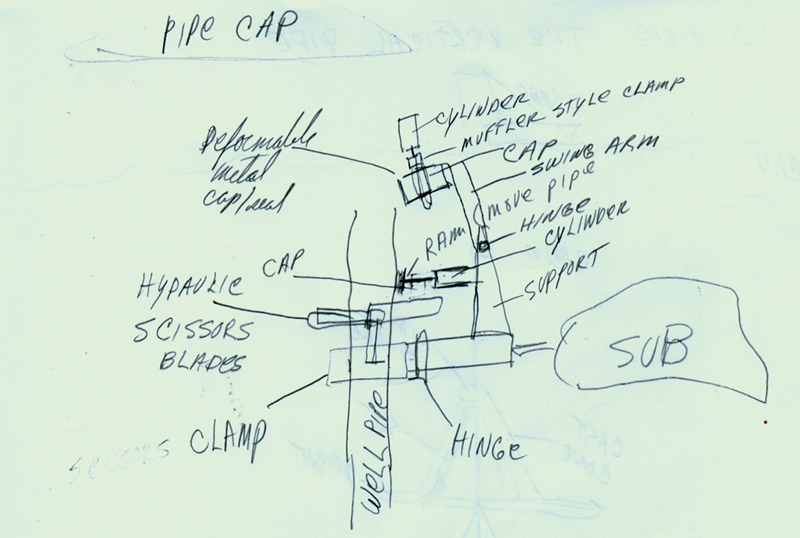

such as the tube opened on one end from a railroad tank car can be settled over the preventer/ and then driven into the ground or rock or whatever. Guided into place by submarine. Lowered by crane with a cable firmly anchored on the enclosed end of the tube. When in place, driven by weights slid from the crane down the cable which then impact on the top of the tube. A cone shaped addition to the top of the tube with weights that correspond will help the process. As it would be better to use air to float the tube on the way down, making it easier for the submarines to guide. That valve would have to be opened and closed / a small hole to insure limited trouble if something goes wrong with closing it. The cable lowering it can also be the elements of a three or four point cone, for guiding weights. It is necessary to remember: you must have a Shock absorber incorporated into the cable line. To allow tensioning from the crane/ but also relief and lowering once the weight does hit the tube in order to push it down. A simple long, hydraulic cylinder is enough/ with suitable line and relief; air pressure potentially the best medium (its safer). As to the cutting edge of the tube, it must be sharpened to cut whatever is in the way. Once you get it over the preventer, if that is still intact, it will do the guiding on the way down. Obviously, the tube MUST be structurally strong enough to withstand the reality. It must also contain a valve and submarine operable hose with quick connect end: SO THAT a submarine can attach the hose, send a single to the valve to open, thereby allowing for filling the tube inside with whatever medium required for sealing materials to be injected if this is necessary. If it is not necessary, then that fitting could potentially be used to recover oil at a MUCH later date. The picture includes an impact zone on top of the tube/ the weight includes a slotted area, bolted back together to add weights onto the cable if desired. The water surge area allows a greater percentage of reliability for a straight drop, the vertical cone also adds that so the impact can be effective. Angled Holes drilled in the weight, will help spin the weight as it drops to achieve a more effective hit. The cables guide the first weight/ the repetitive cones guide the rest. A potential soft (deformable/ or ripped loose) tapered guide area inside the tube (that will not affect the driven down aspects of the work) will improve the chances for putting it safely over the blowout preventer; with submarine guidance. Cutting points may aid in rock, even if it is impossible to drive it down far, the teeth will go for a distance and then double back onto themselves filling the hole. Should driving this down fail to provide an appropriate seal, liquids such as waterproof epoxy must be pumped into the tube to provide that seal. If it seals, and proves to hold/ the possibility of using the oil exists: IF critical care is taken to assure nothing can go wrong with the riser of horizontal piping.. To assist in driving the tube down straight, not only does the cable need the right tension, it also needs the crane to position itself correctly so the weight impacts the appropriate side first. A submarine watches.In the above method of containment by dropping a large tank over the blowout preventer; it IS necessary to hook up a relief line to allow oil pressure to be dissipated/ collect by hose in a surface barge/ and use a shutoff valve that a sub can in fact be assured to operate successfully in either direction. Otherwise you are required to work against the hydraulic pressures created by oil within the tank, and that would make it far more difficult to set into the sea floor. Any horizontal or vertical piping that must be cut/ is done only when the tube is directly overhead/ by crimping the pipe and thereby cutting it like a scissors would do. It is possible, once attached to the pipe, that an alternate mechanism can install a cap over the cut end. No attempt was made to select a crimping device for the cap.

The second method is simply to cut the pipe open at the most appropriate place, and shove a plug into the hole, expanding it to stop the leak. This is dangerous unless the pipe is already flowing full. It is necessary, until these things can be put into operation, that a clinching machine similar to what is called “the jaws of life” only with blunt edges be used by submarine to shut off the pipe in several places along the line, if it is exposed and can realistically be done. The method of cutting the pipe/ moving the pipe to establish an opening/ and plugging the pipe MUST BE an all in one operation.

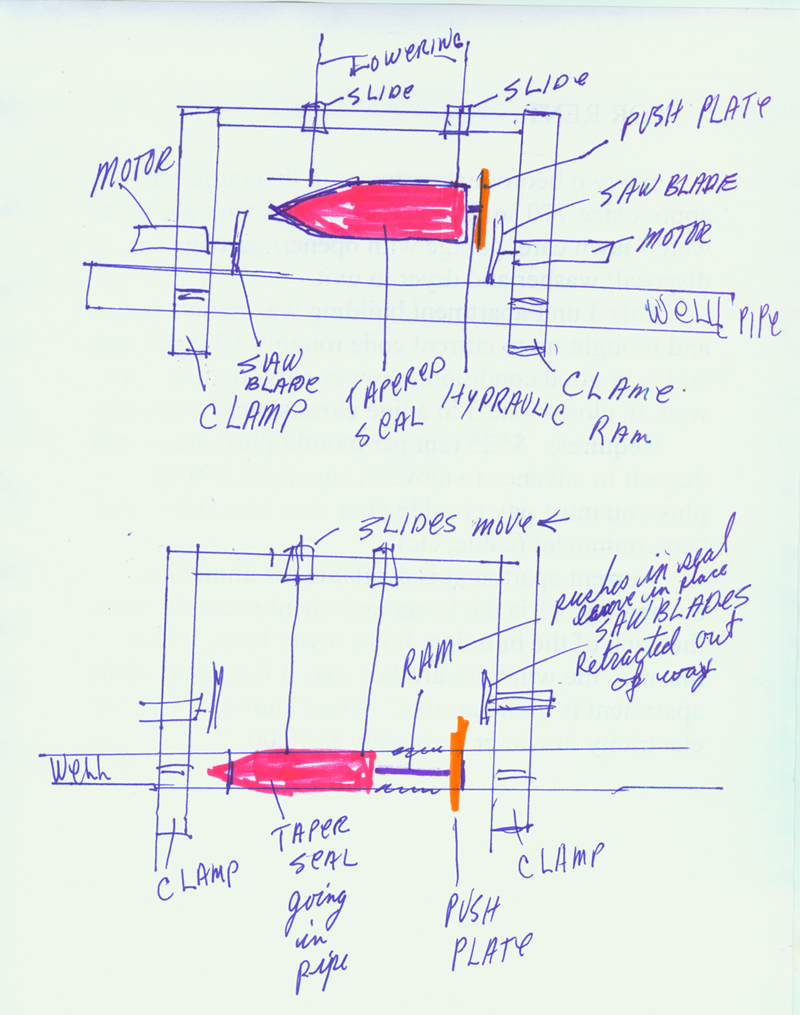

ONE VERSION as shown in the diagram below

in this machine a structure is built to attach to a submarine, with float on top to stabilize (not shown). It is necessary to permanently clamp onto the well pipe. After so doing, there is a saw on each side of the structure to cut a section out of the pipe. Once that is done a tapered seal is lowered from the rising standards which hold the slides, and when in line with the well piping, a hydraulic ram or other is extended, to push the seal into the well piping thereby shutting off the oil. The ram pushes against the opposing cut on the other side of the section cut out. If absolutely necessary, it can be forced with explosives, or it can be mushroomed inside the well piping with explosives/ BUT THAT is risky. The sub disengages and returns to surface. Use a manned sub, make them get one of their toys out, and actually make use of it for life.

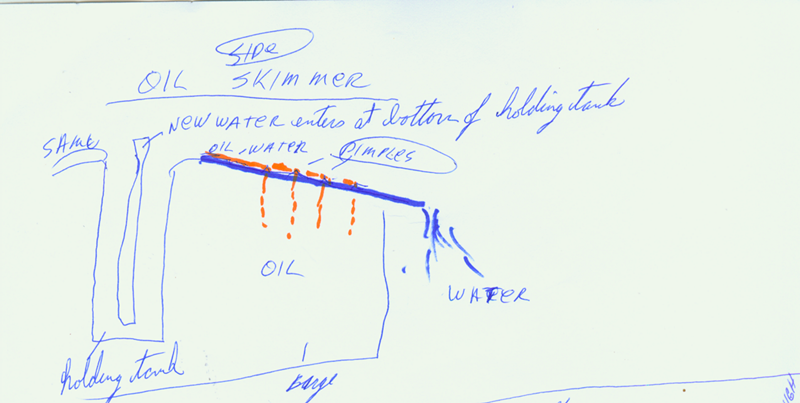

OIL SKIMMER

An alternate method of separating oil, is the flat pan machine, wherein a flat sheet of steel or other material that oil adheres to well is created with holes punched through as a raised surface above the flat/ rather like a pimple with a hole in it, only bigger, and preferably with a raised edge above the hole on the downward side. This machine requires a nearly level grade of not more than ten percent, and a smooth ocean to work. Water is pumped into a holding tank, and filled from the bottom, as the water rises the oil separates. At the top of the holding tank, water and oil flow over the edge, and down the inclined surface of the steel. As oil and water flow down the inclined surface water being under the oil is required to remain below the raised “pimple areas”. Oil being higher than the water overflows the height of the pimple, is caught by the raised edge on the downward side and falls through the hole at the pimple middle. Water exists at the bottom of the flue/ or flat pan edge back into the ocean/ while the oil that goes through the pimple hole is contained within the barge. An appropriate sized pump simply runs twenty four hours a day, while the barge being guided with gps/ or by simply floating in the mess: works until an emptying vessel arrives. Very simple water on a flat surface rises to the top/ therefore if that water were limited to less than .5 inches or so in height from the steel, and moving relatively slowly the oil being on top will rise and fall through a hole appropriately placed into storage below. Angled guide bars to catch the overflow and direct the oil surges that will result in ocean waves should be useful. Holding the barge: on below surface pontoons; so that it rises above the water, will give it a greater stability in higher waves. Making the machine more useful. A square, or circle; rather than a rectangle should be more stable yet. The difference between surface tensions of oil and water are the working mechanisms.

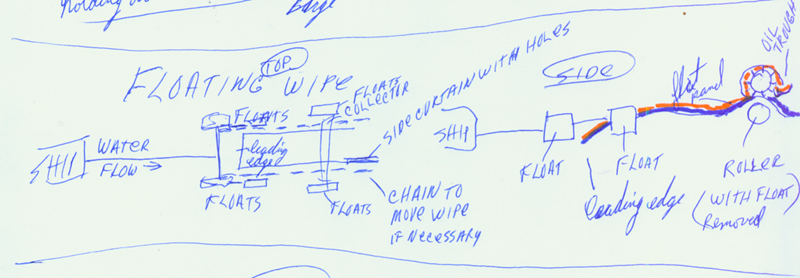

FLOATING WIPE

this is a method of towing a flat panel piece of steel behind a tug. At just below and above surface waters/ floats on the sides. Oil will tend to collect on the steel quickly. The flat piece of steel (not easily bent/ as in spring steel) is then pulled through upper and lower rubber wipes, like in a car windshield wiper blade, that remains in place, or similar to a roller wipe assembly as in the old style ringer washer. Point being that collected oil can be wiped off the steel, as you raise it above the water to run through whatever version of wiping mechanism you have available. The primary water involved is allowed to escape through the side curtains, which flex along the outer edge. Because water is at the bottom, the side curtains allow what is at the lowest level of fluids on the flat panel to escape, leaving more oil, for the wipe. The oil is collected in a small trough above the water line/ and pumped directly into the ship. Calm water only, wiping goes forward and reverse. Add roller chain to the outer edges or as needed to pull it through. an iron structure overhead holding rubber membrane, with spacers at the panel to create openings is reasonable for the curtain.

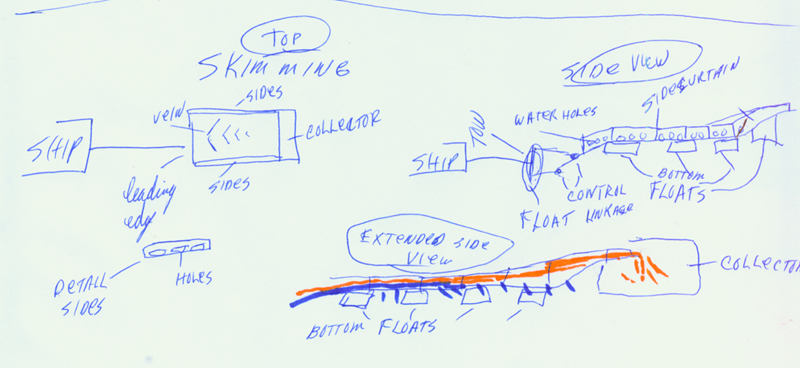

Skimming

in calm seas, the use of a floating piece of steel/ add styro-foam or whatever you like so that the piece of flat steel conforms to the sea surface while towing. With a downward slant on the pickup edge. With adjustable floats to set the height of steel as it flows through the water. Rather like a combine cutting head. As the top surface water is collected (where the oil is) it will be pushed to the back end, by the force of movement through the water. Being raised slightly above the ocean by floats, the water below the oil is allowed to escape in a series of holes that grow smaller as “the mess” is pushed back and up the slope toward the collection box. Gravity forces water out, the majority of what is left is oil and the side walls keep it on the flat panel, while the force of new water pushes the oil into this containment/ collection box at the end of the line. Whereas the sides are enclosed and not allowing escape of fluids at the end of the panel. These which allow freedom of movement by being sectioned at the front of the panel, are more stable or rigid at the rear/ they do not contain small outlets at the very bottom of the side walls to allow the water to escape in the rear area. Some small veins for directing the water to the sides may be necessary. Thereby concentrating the oil at the back end of the box. Once collected: That oil is then pumped through a tube back into the ship towing, or behind the box to a barge collecting. Whether it is best to let the collecting mechanism run free/ or be stretched and thereby more level by using it to tow the barge is trial and error. These can be put into train car like lines so that the water at the end is cleaner. Hooked together pump lines/ require a sump pump in the collector box, to keep the fluids down. Control linkage off the ship tow control the leading edge to adjust the height of water being introduced into the machine.

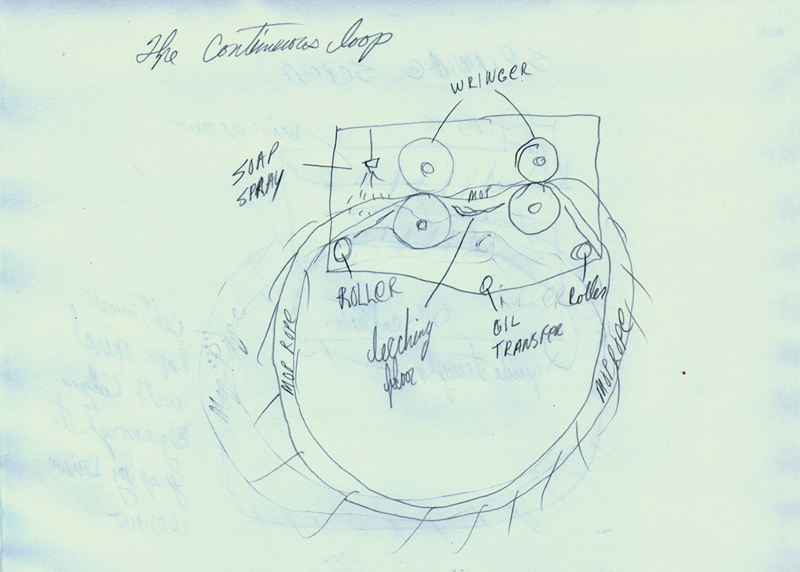

The continuous loop

current mop ropes used to collect oil onto them and being then wrung out on ship is time consuming and inefficient at best. Instead a simple independent system of a single endless rope, that is continually run through a wringer mechanism that floats out at sea with a motor, collects the oil constantly in a small container below, which is hooked up to a common (oil transfer) pipe and feeds back to a waiting barge. Using weights to lower the common transfer pipe with multiple units into the sea, allows an automatic sump to raise the oil into the barge as needed. These can be arranged in a complete circle around the collection barge and with the aid of suitable dividers to keep from tangling, they will collect more, simply by scouring the dividers themselves as well. A common shaft runs system units, for simplicity when ganged together. Electric motors with a common generator on barge. The mechanism uses a roller to introduce the mop rope into the unit. A spray of biodegradable soap is applied/ the mop then goes through the first set of wringers/ is stopped for an interval above the leeching floor, to release soap and oil, and is then sent through a second set of wringers to aid the removal of what is left. Oil collects in the bottom. The height and speed of the mop rope When being raised from ocean surface: prior to being pulled into the machine above the ocean; will aid in releasing the water/ leaving more concentrated oil, prior to entrance into the machine.

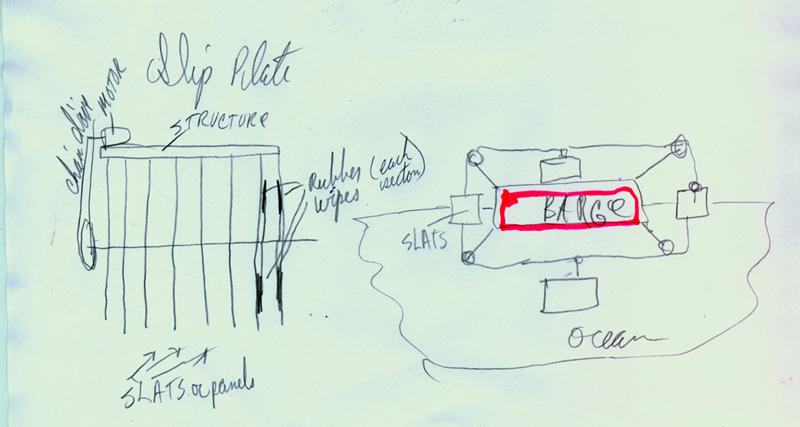

The slip plate version

in this numerous flat panels of steel are lower into the water vertically aligned “like window blind slats/ only in vertical rather than horizontal” the tendency of oil to collect onto the steel/ just like it does to a boat hull. Water and oil passing through the slats is forced to encounter the steel. Is the method of collection. Simple wipes, like “a spinning windshield washer blade” are used to push the collected oil off as these sheets or panels are raised above the water, over the collection container. And then lowered again to repeat the process. A continuous loop can be achieved with a “ferris wheel” like design. The alternate wiping method is a loop operated in a similar fashion which brings the slats over the collector. Wipes begin at the top of the slats and are pulled down/ then returned to top for re-immersion in ocean. “guided chains are used” to direct the incorporated wipes to dump their oil on the collecting pan. An oblong loop for stability/ a circular loop if sufficient structure for stability. ferris wheel construction slats like people baskets hung

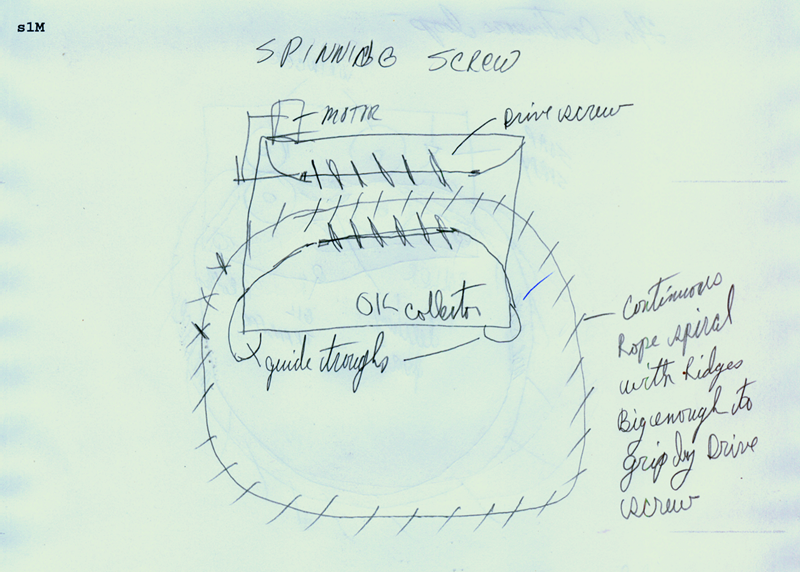

the spinning screw

In the continuous “rope loop” machine, where the roping material is built like a spiral brush. The materials shall be tough enough to be considered an auger spiral. That rope auger collects oil by simple adhesion properties, and a wiping method is incorporated as the screw applies pressures that turns the auger causing the rope to travel through the machine and makes it go up and down within the water. If possible the wiping screw turns fast enough with a thin edge at its outer surface to simply “throw the oil” into a collecting funnel. If not possible all collection is done by pressure applied. There should be three ganged screws working together/ driven together; by surrounding a single rope pressure is applied. While the rope should be big enough to provide for this, the material must also be useful as in possible a cotton rope. Height prior to entrance into the machine allows for dumping excess water. Tapered lead in and lead out is required Blocked into sections this method with the dividers between them can be ganged several together.

The ball method

useful sized balls are released within a containment boom. Those balls collect the oil, either by surface adhesion/ or some type of outer mop design. They are then collected within the ship or barge “and washed, by spinning as in a washer type tub”/ then returned to the boom to repeat the process. Washing could include some type of soap. The water collects in the bottom of the holding, or separation tank/ the oil on top, therefore a pump to remove the water leaves the oil, after a period of time. When separated that oil is then pumped into oil containment tanks for transport/ while the separation tanks return to a new supply of balls for washing. The soap needs to be compatible with all phases of the process. Mechanical scrubbers (mopping ropes that turn inside the spinning drum to further agitate the balls) will be helpful. The mop ropes can be spun at higher speeds at a separate time to collect their oil and prepare for the next time. Primary value is: the oil is on board in controlled conditions, and can be separated. If realistic: some of the collected oil, could be used to heat the water for a more complete separation of oil and water in the holding tanks. A barge, simply sectioned off for this purpose would be useful

squeezing the oil

protecting the most fragile environments/ not human: can be helped by, floating woven mats placed in front of those areas, in relatively calm seas. This is the most complete separation process, however it is also the worst offender as to additional problems. The mats used to collect the oil, they are then run through old fashioned washer ringer type methods of removing the oil. A series of floats held together by rope forms the basic links as in a chain to haul the netting and oil within the wringer. Suitable “sprockets” do the work. Therefore the mat must be made of an enclosed fish netting which contains a compressible material such as foam rubbers/ which will become unusable after a few times. Making this method expensive and problematic. However, the materials are burnable/ shred them as necessary, and using them to fire a coal electric generation plant, is a realistic method for disposal. These ecosystems are worth the expense/ and the foam or other materials can be collected from garbage; “thrown away furniture/ car seats/ old clothes/ etc; across the nation”. Do it now. (Properly sized screen wire, may prove useful/ if you keep it recovery low over the ocean or use a ramp method to pull it in for oil removal; air pressure could blow it out) Oil and water will be collected/ therefore it is necessary to move that into holding/ separation tanks, on top of leeching floors where the water will sink and the oil rise, so that pumps, presses, or whatever can refine the mess.

For faster service,

you can simply tow a large grouping (long narrow bundles which can be tied together into mats; so the materials don’t sink into a mass at the bottom of a net) of materials through the water in nets, when full of oil. A submersible barge (looks like a “ U” / has sidewalls; lowers like a submarine) is lowered so that it goes under the net to collect that grouping. The submersible barge is then raised, holding the materials on a perforated floor; water will mostly fall through that floor. The barge is then pumped out of relatively clean water. And then a suitable press such as a rolling weight: is lowered onto the oil soaked materials to squeeze the oil into the barge below. This is then collected and pumped into the containment oil tanks on the barge. For quicker construction. Pontoons can be placed on the surrounding sides, then using a platform that rises and lowers the groupings can be collected. You can then pump sea water for weight to press the materials, or instead: Raised above a barge and loaded for transport to shore where the material is cleaned and prepared to do this again. Fishing trawlers with their own set of booms can do the same; simply pick up a grouping of materials, lower it into a barge and the barge takes it to shore. It may be necessary to pick up groupings on both sides of the trawler at the same time/ therefore two barges are required, at the same time. Smaller boats can ferry the groupings into position, and hook them; so that larger ships with booms can pick it up. Transport by rail on shore, to less destructive area’s would be realistic. Protect the incubators of seafood and its own food supplies, OR there will be no more fishing.

The functional demand for a pumping mechanism and hose with funnel; [ correctly done, it needs at least 3 funnels, one inside another/ the center funnel being directed onto the main plume of oil/ the second a less concentrated version of oil/ and the third picking up the majority of what remains; each connected to an individual hose/ each going to separate containment tanks] to extend down on top of the leaking oil pipe/ to literally suck up a majority of the oil escaping at the source: is necessary right now. Use a remote controlled sub on an electric line so it does not need to come up, view the oil coming through the piping to adjust/ and have a supertanker anchored or held in position to take the oil aboard, and then to shore. The oil will rise of its own accord, with enough probable pressure to put it over the side of a barge, with control motors for stationary position. The oil aboard will separate over time, and the water then removed. And you pump it to the tanker/ if not directly to the tanker instead. IF you don’t have a sub, MAKE ONE; all it is, is variable speed motor driven propellers capable of moving the hose around/ and a means to identify oil escaping such as a video camera. When it is proven to work correctly the need to drop at least three anchors with remote controlled winches is required to anchor the pipe or hose above the oil outlet, thereby retaining its position. To facilitate that action it is necessary to establish 3 cables on the hose which form a loop, that can be grabbed by submarine. For hookup to an anchor. Simple pull the cable through latches may prove more serviceable with submarines. If you use appropriate plates on the hose during the initial trials these can then be pulled outward, and weights dropped upon them later to provide the anchor points. A more serviceable method, with submarines. If the primary leaking pipe is substantially above the sea floor attaching the retention cables to the pipe itself is a better option/ use guides within the funnel to establish a connection with the pipe, it is then simpler to retain positioning with cables. If sufficient space below the pipe exists, a spring activated/ shock absorber limiting (so that its slow enough not to alter the position of the funnel) hinged door that will simply rotate around the pipe from the funnel, and enclose the entire assembly, pipe and all: and retain its position will do better. A common submersible well pump located in a floating platform with a common electric generator, to transfer the oil/ and your practically done.

If the oil collected becomes a problem, push it down an abandoned oil well for later considerations.

The current intent to drop a large concrete and steel box, MUST have some type of collapse-able bottom to shut out water flow/ and it needs critical slides (something that will seal the pipe/ and be easier for a sub to move than the entire box) that would allow for positioning over the pipe so that a better seal can exist. Otherwise the flow of oil will drag in excess water, that must then be separated. Whether it works or not depends upon the level of sea bottom in relation to the pipe/ they must meet. The addition of inflatable membranes, held within guides to direct them to the surface can be used (like tire inner tubes)/ a remote controlled valve inside the box with an air storage tank to facilitate inflation/ or just pump them full of water, to seal the bottom. To find a level area IF it is possible: once you have the concrete and steel box in place, and sealed/ THEN, if you have placed a robotic “pipe cutter” inside the box/ it is then possible to open the pipe and achieve a greater success. The robot simply stays inside the box. If you have a cutter, then you can have something to crimp the other end of the pipe closed as well, inside the box./ same unit. Put it on a track hung from the top of your box, with a swing arm. Video camera in place/ a pump out so that you can see what you are doing with the robot/ attach the submarine to the top of the box (prior to insertion in the ocean) with retractable line so that it can remain firmly in place and connected to the robot. Then disengage when done.

They are currently about to begin lowering a very heavy concrete dome onto an oil leak presumably at the blowout preventer; although it is unclear if that even actually still exists in place. A tremendous weight can wreck that device even further (a slight lurch, while lowering it, or anything that can destroy more than the machinery can stand) / and cause even more trouble if they fail to be even more careful than it is possible to be. The tank method presented on this site, is better because they can make it neutrally buoyant, to position, and lower it very slowly; using subs or pumps for directional stability, or blow holes and so on. They are drilling new wells, but unless they are very careful here too, an additional well, dug without new safeguards could easily erupt into additional trouble. The failure to contain means: that oil will spread throughout the gulf, and beyond/ ending that food supply forever/ because humanity will not survive the strain/ and other ocean life will be hunted to extinction. Causing even more stress/ demanding WAR Lowering the concrete structure the sea is blackened where the oil is spilling, making it impossible to know where to lower the concrete structure unless there is some realistic type of sonar device that will locate and pinpoint the hole. Although it is without doubt the flow is massive, in absolute darkness/ a tremendous weight can do more harm than good. Making a horrific situation even worse/ unless it is already as bad as it could get. An output beacon placed by sub on the leak itself a receptor inside the concrete chamber to hear that noise: the chamber itself will help focus on that noise. Alternate noise levels placed elsewhere for positioning. The sound of the leak itself is probably enough IF YOU HAVE A RECEIVER OR MICROPHONE for listening inside the chamber BEFORE IT GOES DOWN. So you can position the chamber! Or inside the hose connection that will be made, so a line to the surface can exist simply. That hose should exist prior to lowering so that relief can exist immediately or if not even a small hole around the bottom will not only be excessive and impossible to fix without some type of arrangement inside the chamber. Such as a guillotine knife to slice the pipe or clinch it down/ some type of deformable cushion that can be inflated and caughtby flow to then wedge itself, into the crevice to stop the flow. Something! Or some type of arrangement around the leak thereby identifying its exact position. Or some type of tenting around the concrete structure that widens like a funnel, thereby acting to help clear the water when the valve and hose arrangement is opened to the surface, while the concrete structure is hovering overhead; making it potentially possible to see what you are doing. Or at least directs the oil up and through the concrete so that some idea of this is the right place exists. The tent simply folds away, the material simply tears. Or in other words; light and crush-able. Unless you have the concrete structure full of air and completely held by crane, no clearing will occur/ if you do, it is a limited reprieve unless you are prepared to pump enough air back down the hose to do it again. Or a big enough pump hooked at the surface to simply move the water and oil to the surface so that you can see the concentration level coming out, thereby again having some direct type of reference to this is the proper place / have a barge ready, its mostly oil. If you get it adjusted correctly oil pressure will find its way upward/ which means a tent affair, even out of light materials so long as the tube is big enough to limit pressure inside the tent is enough. Four tent "pyramid shaped iron members", with tent materials to create the funnel ending with a hole at the apex for hose relief, is an alternate method. Just lowering a weight into the water hoping, is not enough. The concrete weight is intended to hold the pressures down/ but if you are removing enough pressure to balance the oil and direct it into the funnel; the pyramid structure defined above will work just as well; so long as you can keep the hose from moving substantially. "Think big tent". Think about how to use the tent and hose to direct the concrete structure down on top of it; if necessary; sounding devices/ laser devices/ something. Which if you are planning to do that would require a flexible hose, and a cable hooked to a tent leg/ so that when the concrete dome went down you could simply pull the hose aside drop down on the tent, and crush the old hose instead of disconnecting it. the tent needs some type of tensioning device to register when the balance between suction and pressure is acceptable. Perhaps even a relief valve of some type, which could be as simple as a seam which pulls apart under pressure, and then is pulled back by springs. Remember to be able to re-hook if necessary; on either device: that would necessitate some type of float and line that could be released remotely to bring up the heavier line; something. If you put the tent down first, it will allow you to prepare everything necessary for lowering the concrete structure as a more permanent fix. Or at least potentially see what the situation is, more clearly after a few hours time: by adding sensors within the tent prior to lowering it/ wires up the hose. In terms of dealing with the other massive leak, the use of a large tent itself, in the shape of a pyramid or teepee allows the opportunity to direct the oil to the apex hole where it is immediately hosed to the barge on top of the ocean. Immediate relief allows for minimal material, as it is then just acting as a separation layer between water and oil. No "great weight" needed, so long as you continue removing the oil. Plenty of tents already made just change the top, to apply a hose, or two. Where debris makes covering nearly impossible/ again the use of a large ship at speed is a tremendous source of energy; like pulling a truck with a stretch strap once you get attached, there is plenty of energy available to move the debris: but DO use a warship of some kind because the weight applied to the rear of the pulling ship WILL require a very heavy hull. Otherwise the use of a tent that folds out like an umbrella will give you the opportunity to thread the supports through as best you can. The tent material itself; can then to dropped from the top/ cut as required and with surplus material re-seamed IF you have prepared the material with suitable guides to cut between and a rope or cable or velcro or something to not only pull it back together around the obstruction, but hold it in place as well. Some type of air bag or something, with a weight to counter act the air/ or an air bag that will extend from the support taking up that space. Or a spring loaded bag that will move across the opening with material if released. Or multiple layers inside the tent which act like individual guides, tied to the tent structure on a horizontal spring arm, which will deflect and return to position directing oil to the funnel above. The flow itself will direct most oil, if you simply keep the material out of the way. The flow will rise up the tent material into the seamless dome if its done correctly; openings at the top of each individual flap so the oil that goes between layers can get out into the tent dome. The support arms that define the tent itself, need not be anchored unless there is current. However to move the structure on the sea floor surface, some type of hook up is necessary. An anchor and a cable if you have the structure so rigged and it moves. Inside the tent a flexible joint at the apex for primary oil and an extendable small funnel tied to the supports with winches that must work together for movement around on the inside of the tent: can be used to funnel more oil than water into this main line. At least three winches with one winch to extend or contract the adjoining pipe between the apex and actual funnel for concentrated oil. Strain gauges if nothing else to determine if the winches are ok. Check the oil stream to identify where to direct. A secondary mixed oil line is incorporated at the apex of the tent to establish another hose going up to surface which is then used to fill an alternate barge with less concentrated oil. This tent dome NEEDS a big enough hose at the top/ or it needs the correctly sized pump that cannot be stopped, or the tent inflates and is destroyed. Too much pump and the tent deflates and is destroyed/ therefore a variable opening or a properly sized pipe is necessary. Strain gauges on the bottom of tent structure frames can weight the effects. Or just abandon this separation in favor of time saved. Most oil/ water is pumped into an abandoned oil well for time separation, and later removal. IF they do break off the well head, leaving it impossible to re-hook or remove or use their concrete dome. Or the dome cannot be removed, because it is partially working/ a tent over the top will have to do; with some type of adaption to let the surface delivery hose be included, and then tightened around that hose when in place. Thread the hose through the tent material prior to lowering if you can, with simple lacing to draw it up. A second method is if flexible to pull the hose down to the sea floor so it need not interfere with the collection dome in the tent. If it is a tent, the flexible sides would allow entry at a later date/ on the sea floor to attempt repairs. Adding sufficient pumping volume increases visibility inside the tent so long as you don't collapse or tear the structure. If the well casing is open and exposed a torpedo style plug can be inserted, and deformed from the inside to plug the hole. If the pressure is enormous that plug would contain an escape valve for pressure reduction and later closure after the plug is made. Anchor points in the sea floor allow plugging to go forward. If necessary, a smaller steel dome with working valve and drilling anchors to establish hold on the sea floor can be used. More at www.justtalking3.infoAll are free (everything on the sites I provide are free) to whoever uses the tool for environmental or more simply LIFE FIRST purposes. Make money if you can/ but remember: a world without life, is an empty world/ and it takes a long time to recover from tragedies like this. Do what you can do. Fight for the money later. Collection of oil is open to all/ the amount of oil you actually collect determines what you are paid. Choose whatever method you wish. Be adequate with the pay scale to encourage real efforts. Let any and all who would claim: “the little guy has no place here”/ be legally liable for any and all oil and its damages that they miss. It is the “experts” that brought this disaster/ it is the experts that failed in every sense of the word, with Katrina before and after/ it is the media that propagates lies, and belief without questions that matter. GO DO THE WORK REQUIRED, and demand payment from your president (did he not promise “spare no expense”) /your governor/ from your local politicians/ from the business environment who WILL lose tremendous amounts of money/ from the nation and sea food industries. Go do the work that is necessary to do, and collect when you prove “you were right”. Fail to protect your environment, and WHAT will you have left? Do, what needs to be done, yourselves. Your experts failed/ your leaders failed/ your universities failed/ your media failed/ your money failed/ your government of employees is failing/ your greed is a disease. ETC, ETC, ETC. Get your ass out into the ocean, and do whatever it is that you believe might help, TODAY/ and worry about the money later. No food, not life/ no water, no life/ no oxygen, no life; and NOT one decision putting life first exists, from those who lead you. NOT one true intent to help exists from the media who propagate lies, about everything. NOT more than a tiny few, investigate or examine reality for truth; all choose to let audio and visual media “TELL them what to think”/ BECAUSE YOUR LAZY/ or because YOUR GREEDY/ or because someone else’s greed, sloth, and bastard excuse for want consumed by selfishness; has made them slaves (just can’t do more, I have to survive myself). This is just the first tiny step into hell! Lose a third of the seafood for this nation; and you too will begin to learn what starvation is. Because irrigation will end/ the aquifers are being totally drained. Genetic mutilation is crucifying life, and there will be nothing left. The pollinators are dying. The terrorists are trying to light this entire world on fire with fusion/ or blow it up with energy released that does NOT “obey time”. And “a thousand more threats”, all because greed has made the majority dead or dying, “between the ears”. WAKE UP, and DEMAND ACCOUNTABILITY/ DEMAND: WHAT, IS OUR TRUTH GOING TO BE! OUR FUTURE? Because as is seen in this catastrophe; What is hidden from view, is already destroying your world/ your economy/ your nation/ your life/ and assassinating your children. Because YOU don’t care enough to work for life itself, rather than money. EVEN THOUGH the money is bad/ you STILL choose it. Shame on you.

Remember this, that liars lie! Therefore when you hear “the experts” collected “lots of oil” go down to wherever it is that this “oil” has to be delivered; and see for yourselves if it isn’t basically all water instead. Their ways are nearly useless/ their bragging little more than lies. Make them prove their reality, and establish the hours run on diesel power/ to identify whether they are simply dumping their own fuel and oil into the mix to “make them look better”.

AS YOU DEAL WITH THIS TRAGEDY/ CONSIDER FUSION, TIME IS RUNNING OUT.

As we approach what could easily be the last hours of earth, it is absolutely necessary to ask WHY: would any human being on earth, gamble with every life/ even an entire living planet, just to prove they can. The experiment at the national ignition facility scheduled soon; “To create a star/ burning globe of atomic materials lit on fire”. Is functionally possible; just like any other atomic environment: the ignition of this star could BE SELF-SUSTAINING! If not this time, certainly the next, or perhaps the next/ after all russian roulette only kills one time, no matter how many times you spin the barrel on the gun. The world dies only once/ just like you.

But that does not answer the question of why, would any person, or any group of people/ OR any leadership of country or community allow the experiments that can kill a world? Like the oil spill in the gulf of mexico: “The university diploma/ and its propaganda machine of media and government” all say, HELL it will be wonderful. But like the oil spill, even a damn fool should know, WHEN YOU CANNOT AFFORD TO BE WRONG: at a minium a simple shutoff valve at the bottom of the ocean with means to turn off the supply should exist with “the flip of a switch”. But no, “ the smart people” NEVER know one thousandth of what they think they know for sure; to damn proud, to let truth decide, or reality lead. The obvious famous last words that are consistent throughout the university is: “Don’t worry, I’m sure they know what they are doing”. Its only hell after all/ its only Armageddon (nature in chaos/ genetic mutilation)/ its only the entire planet a “lake of fire”/ or at CERN, just the planet exploding into dust; Shit yes, they do know what they are doing/ that must be why then: THEY SIMPLY WANT TO KILL US ALL, to prove they are gods. Well technically satan/ but who’s keeping track, ain’t that right. The cheerleaders of media, military, and government got it all figured out: first they make you fear/ then they sell you “the antidote” for absolute slavery. Except of course there is no antidote for any of what the university is doing. And let us not forget the religious: or the prophecy “they will be having weddings, etc/ not a clue, and then the whole world ends”. Gee, what could go wrong/ men playing god, while other men let them. Playing with energies that can reach beyond the dimensions of time/ and create the end of time. THEY DO KNOW, what can go wrong/ but choose to do so anyway; because “they are satan”. Disciplines, order, and balance that give life its form and boundaries of existence/ its everything: THEY DO KNOW what can go wrong/ but choose to do so anyway; because “they are satan”. HELL, why not gamble with all life/ what could go wrong, PLAYING GOD. Well besides no life at all.

When we look at our reality, and understand EVERYTHING that is leadership in america; is run by “university diplomas”. Doesn’t matter what, they organized/ they warred against the rest. They established trench warfare, and made their experts the weapon of choice, their media “fools’ gold” for the masses. They pirated the government, and stole the money. They chose the endless seas of pollution/ resource depletion/ poisons/ failure/ and the disease of arrogance so vast and prolific: from a “thousand different ways, an entire earth is threatened with extinction”. Do you really think weapons of mass destruction are your friend? Shame on you.

Not to worry though, the same people who have made war against you for decades; stripped/ killed/ raped/ ravaged/ murdered the future/ manipulated/ strangled/ terrified/ feared/ stole/ enslaved/ proved to be the laziest generation of this earth; and so on: Are going to save you. That’s what they experiment with absolute chaos for: “to save you/ from time”. You don’t care right/ so what if you dead; lets all play follow the leader/ lets all bury life on earth: cause you don’t care enough to say “nothing”.

What can this generation be compared too? The answer is pearl harbor Hawaii/ December 7, 1941 enemy planes on the horizon/ BUT SURELY IT CAN’T BE SO! Hell no/ why that would be a catastrophe; “Go back to sleep”. No one is that stupid, right? No one is that vile, would do something so horrific as gamble with all life on earth, right? Or, perhaps “the nazi’s or japaneze leadership or old” just has a new disguise/ and a new weapon. Don’t need no damn little atomic bomb no more: KILL EM ALL. What could go wrong? Doesn’t matter/ cause stupidity is rampant; and without the media to tell them what to think; “The disease of university” has proven to be: death without a whimper. An infection so virulent, don’t even need to pretend/ the fantasy and delusion have prepared the flood of fire, and none have a clue. Because they are sure: “they wouldn’t kill us/ no sir, not them, the media tells us its true”. Don’t need no damn brain, the media tells us what to think. Ain’t that so? And they don’t want to die either/ so why shouldn’t we believe them? Prove it!

So lets review: the university diploma leads life in america/ there cannot be an argument, it’s the simple truth.

1. We are bankrupt, living on a credit card that will fail; “their fault: indeed it is”.

2. We are surrounded by pollution, the university selling the toxins in every form through the media: for the sake of greed/ “its all good”. Yet trillions of tons have been produced in the manufacture and use; do you really believe no tragedy is coming/ is here, even if you cannot see it yet. Not to worry, “they will tell you when to worry” isn’t that right. Hell yes, after they change the numbers a time or two/ or cannot hide it anymore. Oh well, too late is too late/ can’t kill us now “we’re dead”.

3. Threats beyond number/ and not one single decision of government, university, military, media, or business: for the sake of LIFE MUST BE FIRST! Just playing, just pretending to keep the protestors at bay. Just a media working to subdue and constrain every public outcry. But not one true critical effort to establish and define by examination or investigation the facts that will determine our future/ our death as life on this planet.

4. Too smart to be fearful/ “Cause its fun, like going to a horror show; make me scared/ so I can say: I AM A WINNER”. TOO BAD real life is not that way/ where HORROR IS HORROR/ and tragedy is TRAGEDY/ and CATASTROPHE, is a decision that should never have been made. Not to worry though; cause your brave, aren’t you? HELL YES, can’t make the fool scared. Cause the smart ones KNOW ABSOLUTELY EVERYTHING/ and the dumb fools KNOW ABSOLUTELY EVERYTHING as well: cause both live in delusion and fantasy. Making lies.

Either human life will arise, or die. Either this planet is worth protecting from those human beings that are worthy of death, by firing squad: or you are dead. When any human crosses the line, to become a terrorist NOT even against another nation/ BUT LITERALLY against the world itself: by gambling with every life. That human being does not deserve to live. Being wrong, is like the oil spill in the gulf: every promise possible, “NOTHING will go wrong/ WE got it all under control”. Only where it is ALL life on earth that dies instead of environmental catastrophe. Is that not a true global terrorist? The world dies only one time, there is no going back! Try thinking for even a second/ and you KNOW this is true. Wake up or die, it’s a choice.

In an alternate environmental problem, visual media has displayed Hawaii invaded with wasps/ and people trying to eradicate them through the day. That is absurd, because the hive/ nest is active through all daylight hours. To kill them, it is necessary to wait till dark/ and then poison them, or whatever it is that you will do. To aid in this, a simple inventors mechanism with a photocell and a battery, would simply operate a catch, to open the door and release a suitable dust. Placed on a pedestal over the nest/ activated at dark: the nest is gone, next day. IT IS necessary to study behavioral habits.

c