Grain drying; the fundamentals which do need to be fully investigated by USDA and others to determine exactly at which points in the storage of grain a real life scenario of additional fan usage is necessary. Since this is work: they haven’t done it/ will never do it; as is the constant of a university education. “science”; found a grain of sand/ done for the decade. Nonetheless; we begin with; What types of monitoring are useful, etc.

Primary importance is the movement of water through the grain; and that is determined by outside temperature variations, heating on one side of the bin by the sun, humidity levels when the fan is running. And grain temperature variations within the bin. Most important is temperature variations/ as an indicator of something is now wrong. That generally begins in one small spot/ but heat radiates out.

Assuming a level, properly dried grain in storage from the field. The simple test of dryness is: walking on top of the grain; if you stand like on a pavement (not dry)/ if you sink in 6-10 inches (like walking in snow) throughout the bin it is dry. From that point on; it is the condensation scale that determines if mold will grow. Water has to be transferred in: to create conditions for molding. Water/ condensation: is transferred by air flow; as is heat or cold conduction/ which brings water in with it. Any air leakage will result in molding (as is seen around the bin door in many cases): because condensation flows from hot, to cold (like water on, your glass of ice water in summer).

Moisture moves in and out of a bin in accordance with the dew point/ and air exchanges. The difference in temperature, and outside air humidity that causes condensation to appear on a colder object/ or disappear as it warms up. These variations allow for mold to grow. Air movement in a grain bin is limited by the base compaction levels of the grain, which are different for every type of grain. CORN is used in this example. As air does flow through it when properly dried, more easily than some others. Warm air moves to cold, to deposit moisture/ or cold moves to warm, releasing moisture.

Once the bin is adequately dried, it will be turned off/ and later fans will be turned on to achieve a lower, freezer like, temperature for the grain; to inhibit mold growth. But that can turn against you: as a bin kept too cold; promotes cold grain causes condensation of moisture, on the grain. Which can then turn to ice/ which as it warms will turn to mold; and causes grain to rot. Therefore you must maintain a realistic GRAIN temperature slightly above the dew point or better: or keep it cold enough, with little or no air exchanges in the bin. Generally not hard; unless too cold, or too warm. Be aware of any unexpected grain temperature change (south side warms more); as that causes air movements to occur. With grain ten degrees close to the relative air dew point for the purposes of discussion; will likely not result in trouble; unless you already have trouble in the grain. Air exchange is: cold air falls through grain/ and warm air rises through grain; tomorrow it can go the other way. A sealed bin is like a sealed jar: no trouble inside good. On the other hand, if some degree of mold inside already; then sealing that inside is bad. Dependent upon if the grain bin is sealed or not/ and to what extent your are certain of your drying. Sealing a bin requires a “rubber roof or plastic layer on top; of the grain”/ closing the bottom gap between sides and floor is a major leak; sealed fan and auger opening; limits air exchanges as well. A TOP LAYER works; But you have to deal with that by hanging it from the roof, putting it in a box, or whatever; when emptying, or filling the bin/ it will be in the way. But if plastic, not too heavy. Sides can be sealed with magnetic strips. Sensors are small, and can be pushed in

The small transfer of heat or cold; is what causes air leakage, to spoil grain; which then points to rot in specific areas. But that should not affect the entire grain bin; over winter. Generally only trouble during long storage. Because it is the amount of heat transfer (air flow) that decides. Beyond these minimum levels of trouble; the farther away you are, on the dry side; from a outside dew point the better off you are. But if your dew point (cold grain temperature versus outside warming temperature with high humidity) is over ten degrees on scale: proving condensation will migrate into the bin: using a fan at the appropriate time can be necessary. But once you start air exchanges, you must achieve a reasonable sustainable, “proper temperature”/ it must not be producing condensation in the bin. Be aware there is minimal effect levels of condensation/ but that means “sweating to the extreme” condensation; can occur as well: dependent mostly on humidity levels.

Never use a fan during extremely cold nights: as that causes your dew point to dramatically alter itself. Moisture falls, “like fog”, in extreme cold. The top of the bin grain, seals itself off by turning into ice. Extremely cold top grain surfaces draw moisture from lower in the bin grain (drawing moisture from the grain up), and into the area where water will freeze on top. Hotter air rises too; so the bin grain loses its moisture content in the lower 2/3 of the bin to create the ice in the upper 1/3 of the bin; and then shrinks in accordance with that moisture loss. Leaving the ice held up by the sides of the bin; and may cause it to partially collapse. Causing a hidden cavity that can collapse in the grain bin; when emptying: because it is not “bridged up”; potentially ending your life if you walk on it. Big losses, in grain quality and rot; if you do not remove/ empty the bin quickly.

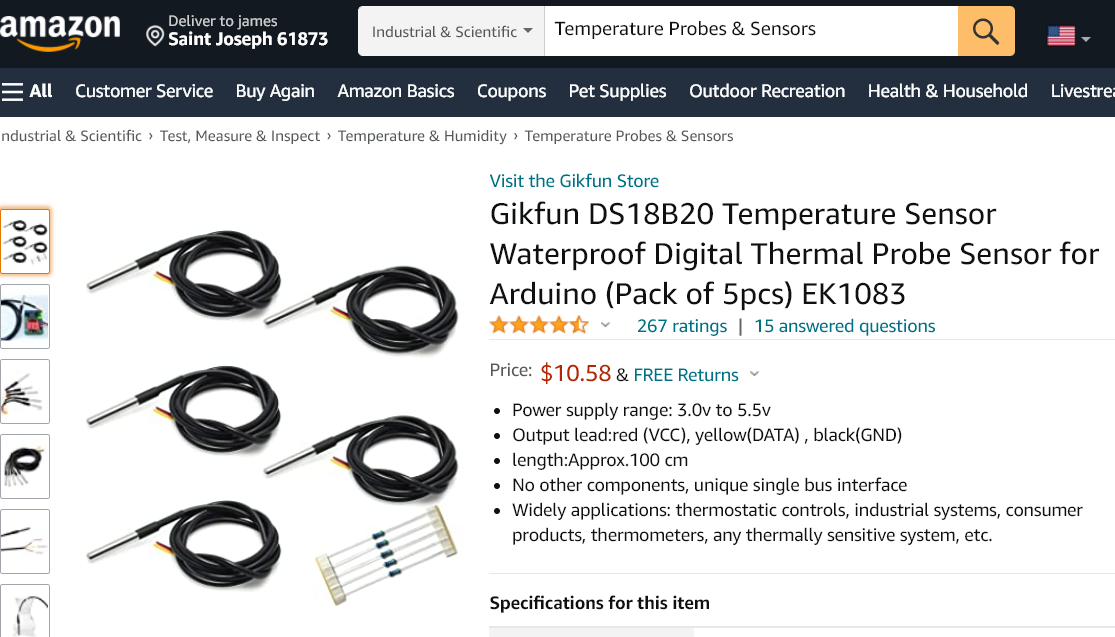

Without taking the temperature of the grain; you cannot know what the inside is doing. Take the temperatures weekly, until you are familiar with your bin; is a good plan. So you can recognize on this particular day at these temperatures and humidity: the grain has risen in temperature or dropped in temperature/ with or without a fan. Because it is the change in temperatures that indicates trouble; beyond what is otherwise expected. Generally, for that reason; it is best to take the grain temperature from the south side of the bin if it is exposed to the sun; more is better, but one probe is enough unless you did not dry it properly/ or have a leak in the roof. Shove the probe in at various depths until you get familiar with it. You can drill an appropriate sized hole in the bin side at a place you find acceptable; cut threads into that hole, and insert a short pipe: which then gets a pipe cap when not in use. There are cheap and small temperature senders today, which can be read with common cheap multi-meters. Or if you don’t have a stirator type machine inside the bin; you can simply hang the temperature senders, with wires outside to read it. If you have a stirator: dragging a temperature/ humidity sender (put it on a spring wire; decide the depth you want it to run at/ or just use a small perforated pipe trailing the auger, at 3-5 feet into the grain when full/ air flow inside the pipe will direct temperature and humidity up, into the sensor box on top; wireless will keep you informed) behind the auger; will produce a reading throughout the bin when running: wireless can send it to your phone, or automatic shutoff.

Because the average humidity for October to march is between 50-65 at 3pm afternoon- 70-80% 6am morning humidity. The best time for cooling grain would have to be early evening; as the temperature falls. Learn to know how long it takes with your equipment: to cool a bin: several nights (have to leave it open/ drying) or one night (stable). Costs money to aerate/ pays to know. A simple: 6 hours is probably enough for aerating most bins; already dried. Temperature change by one degree indicates more than one air exchange; assuming a twenty degree difference, or more. You will never achieve “a value” by re-wetting grain: the realities as well as environmental costs are too great/ your child, nor this world; does not deserve to pay. It is a fools game.

You should recognize; that most hearing damage comes from constant noise rather than intermittent noise. Most damage from high frequency sound, rather than low; it matters. While very few bin fans are below the damaging decimal range; that fact then does matter to your family and your own future. As is evident throughout the farming community; with damaged hearing. Their ears and yours, are subject to damage; Noise does matter/ particularly over time; and the neighbors think so too. The most effective method of removing noise to dry a bin is to use a fan INSIDE the bin [free to all]. Placed correctly in the center; with appropriate methods for “lifting the support members” for grain removal/ and the noise will be limited for all. A center tube to pull a damaged fan up if needed; with appropriate air intake or release to be used. This should include “gates inside the tube”: so as to direct air to one quarter of the bin; in case of molding present. Grain, such as soybeans; not easily dried due to limited air flow: can be dealt with by using corrugated drain pipe, with caps/ to divide up the space: placed vertically off the floor as needed; it opens the grain into smaller units. The “screw in plugs for these pipes”/ can let you regulate where the air goes/ and where in depth it will stop; by turning down the plug into the pipe. This same technique will aid in drying bins that do not use a stirator/ although it may be best to block the bottom up, and open the top to redirect air flow. These are light enough to not greatly interfere with unloading. If you carry the grain beyond winter; you must monitor and control the temperature (warm it up) to limit air exchange due to temperature changes: based upon dew point. Sealing the bin, helps; but you must be realistic with the temperatures needed (hard to do, but open it up, to aerate; with dramatic temperature changes). PRIMARY to all grain storage is keeping the temperature under control, and basically same, throughout the bin.

The end result of it: the failure to watch your temperature of grain/ remove unwanted air flow from the bin/ and pay attention to the condensation scale: so you do not aerate at the wrong times; are all essential to maintaining a quality product for sale. Paying you back in money/ and stopping irrelevant aeration which costs you money. Environmental damages do occur; “an overheating world/ oxygen consumption/ pollution/ mining/ resource losses; and so on with all electrical generation other than “honestly green”: with irrelevant aeration.

As to noise generation: few people I have talked to do not reply “yes I have some noise in my ears constantly”; as is consistent with tinnitus. BUT BE WARNED: TINNITUS has many varying levels of damage. From minimal, which can be easily tolerated/ to extreme; which is “like a smoke detector alarm at ¾ volume in each ear”/ even louder, it causes ear drums to break/ and even deafness; which can last a few hours or forever. That gives you tunnel vision/ and unlike the concept “can’t hear birds or such”/ it extends into the sounds a body makes like breathing or a heartbeat; which are not noticed until they aren’t there any more: NO SMALL THING! These are frequency problems, not volume problems: its like the shock absorb-er that stops your inner ear once the noise stops: NO LONGER functions, and it just keeps vibrating for weeks, if harsh noise; at times. So, how much are your ears really worth? MORE, than you can imagine/ and its not just you: and it never goes away, changing lives, work, relationships, and more. “it will heal/ is replaced with its a disability”.

https://www.raspberrypi.com/products/raspberry-pi-zero-w/ ten dollars+ readout

just something to get you started: these would have to be wire extended/ but finding a suitable IT technician should be no problem.

Excessive behaviors, “like excessive aeration”; are examples of obsessive/ compulsive behavior. These exist as a testament to the cost of doing something wrong/ and then spending your life, to fight against doing that again. With what are conceived as disciplines by the doer/ but are in fact; a reality of mental disorder. Keeping the threat of what can go wrong, because it has: close by. Means the reality of what has caused this “failure/ whatever it is”; in the beginning; was never yet resolved. Life is not a fight, nor is it a game. Living means to accept the cost, and achieve order; by balancing your own impacts upon this world, and its living companions; who share life.

A FOOTNOTE: excessive field drainage/ tilling; produces the certainty, “your aquifer (water supply) cannot be recharged”/ because you chose to do this.

The insects you hate; are a base food link, in the entire chain of life on land: no food/ no life; and that means the things you depend upon/ must also find something to eat. Whereas sterilization/ mutilation of all genetic plants; is another: COST of “university”: as reality will prove/ they are removing all nature created; pant defenses to increase yields. Opening the entire species and sub-species; to extinction. Did you know “corn is a grass”?

As is rice, wheat, oats, barley, and more. Thereby we understand: a “pandemic disease” in one grass/ can turn into the end of the base food link in nearly, all of our own lives. And that is only one species of our reality and connection with life and living: that universities have invaded. To play god.

but hey: with an entire world on the edge of extinction, “why should you care”? after all, fifty years after chemicals came into use here/ now the water is basically undrinkable, when before it was “perfect”. So, why care, its just poison/ RIGHT? “Hasn’t happened yet”/ now turns into, we cannot fix this anymore.

of note: I know of a couple people, who were long time welders/ now going blind. The most likely, primary cause: the difference between welders of the past and today is: the self dimming welding helmet/ which darkens when an arc is formed. Even the best helmets allow arc light to come into view/ a constant repetition of that, “every day”; is a challenge to any human eye. As the price of repeated “like looking at the sun”; arc viewing will always be bad. There are two versions in use: the cheaper one has two sensors/ the expensive one has four; nobody doing any extensive work should use a cheap one. I do use a cheap one “if I need another hand, for starting”/ otherwise I use the old style “guess where you are at”. As has been used since electric arc welding began. Reality knows we need or want electric welding/ but make no mistake, if your eyes are not “comfortable/ ok”, at the end of the day: make adjustments in what you do. Aluminum welding is particularly bad, with much more intensive light: a secondary old style #8 goggles, along with a front shield #__as needed; might be necessary; so that nothing peeks in from the side.

a conclusion of this is: I have several neighbors with bins which in the past ran for up to 8 weeks or even more one wet year. Today with global warming, and the industrialization of agriculture; most goes directly to the elevator, which provides more noise. Particularly since it was industrialized as well: bringing grain to ship from fifty miles away by truck. A failure, because trains are so much more efficient. A train ships one million bushels of grain; for a few gallons of fuel per mile/ while a truck ships 800 bushel of grain; making 1250 trucks required to do the same thing: SEE THE DIFFERENCE? all the heat, pollution, resource lost, oxygen consumed, noise! Just train engines sitting on the track going nowhere: are still producing all those losses for life and world. While reality shouts: WE NEED A JOB/ the truth shouts back: WE NEED A WORLD, AND IT IS DYING! time to change this, for life and world. IT IS A LONG LIST NEEDED, or we won’t survive; the choices you made: to insist “let the children die, so we don’t have to pay”. to allow, university terrorists to completely destroy life and planet; with your cult worshiping; screaming make life easy for me/ even though there are consequences: ONLY THE CHILDREN have to pay. “eternity WILL remember that decision”/ and who made it.

There are now 1.5 million bushel trains leaving here.

Loading trains is noise/ trains idling on the siding is noise/ elevators are noise; etc. But worst of all lesser things; is a neighbor 1 mile from me with 5 bins; he apparently dries only with air/ because he runs twice or more as long as anyone else. This has been a dry year; nobody reports wet grain; but this year after all the rest were done for weeks; he filled one last 4000 bushel bin, and then ran it for roughly 350 hours; even though no expectation for more than perhaps 3% drying (18%) could surely exist. Before global warming; the average grain moisture put into the bin was between 22-25% moisture, with some at 30% or more: which adds weeks of fans running 24 hours a day. Just one of the five fans registers 52 decibels at my back door. Add four more, running constantly for four weeks; plus more/ and the cost of drying corn becomes more clear. Another neighbor one mile away uses a grain vacuum: 63 decibels at my back door, at higher pitch. Or more distinctly there are reasons why agriculture among many others experience hearing trouble; and nearly all complain or “noise in their ears”. constantly telling me “its nothing”. yet if it gets a little worse, that noise in my ears is roughly equivalent to “a smoke detector; screaming at about 3/4 volume: 24/7, FOR WEEKS. Which can then cause deafness (temporary or not)/ ear drums to break/ remove options from life; and much more.

While drying is absolutely necessary: allowing fans to exist that are far more noisy than they need to be/ IS NOT. Drying without heat, which adds double time; is not. Laws do need to exist: to control “criminal trespass by noise; outside of cities”/ OR deliberate reduction in noise to what must be necessary; by changing fan blades; putting fans inside the bin, to reduce noise: not particularly hard engineering or expensive. A free gift of the idea. Large squirrel cage; slow fans with belt drive; are by far the quietest; the problem, starting a large mass into motion: is easily and cheaply altered by a simple electronic device which pulse starts the motor. to attain motion in increments that do not tax the motor (a public gift; claimed invention). OR on very large fans; to simply incorporate the torque converter into the direct drive; between motor and fan; will easily function as well; including an electric clutch if you wish. Although carefully designed and built fan blades can be used in direct drive: they are rarely built. In other words, while agriculture must dry grain to keep it: when the violation of another space beyond yours; is mandatory by what you do/ then your neighbors do have a right to expect: YOU WILL do what can be done, to respect their lives, as well as your money. and spend the money needed; create the laws required: to be as quiet as you realistically can! That fact extends to all noise generation, in all categories: BECAUSE Tinnitus, is a bad thing/ I KNOW, because I have it; and mine came from a tractor cab; that made others deaf/ but my dad was certain we were too tough to be affected. He was wrong, and could not listen.

The lessons needed to learn by those drying corn INCLUDE: when drying only with air: you CANNOT dry anything when the temperature drops below roughly 55 degrees. As night time nearly always is/ which means, you are cooling the bin at night, generally pumping nearly as much moisture in, as you took out in the day. And simply spending money/ while in the next day you have to warm it up again before you dry anything. Drying with heat, requires double the fuel at night; due to temperature drop/ but when in a hurry, sometimes required. But with global warming that is basically untrue today. YOUR “experts”; need to do their job; and establish a valued table for what is realistic drying. Since few actual family farms exist: you no longer have the claim “its fair”/ because they cannot do it back to you; anymore. The vast majority of drying bins no longer sit on the “farmer” home place; but are scattered around on what was farmer home sites; that no longer exist. And that means; you are taking advantage/ by making the others pay for your decision to save money. Which is the only reason, the loud noises exist: “didn’t want to pay for quiet fans”/ we don’t care. The demand to monopolize elevators; was a direct result of US debt/ because they sold the railroad to Canada: and as always there were consequences.

There could be litigation: ‘”you made the noise you keep the noise/ as best you can”. As would be changes shall be made. The reality being: those who do chase after the money can pay for the damages they do.

It should be noted: that this became a big shipping elevator some years back/ because one of the major seed companies: sold more seed of a particular kind than they could supply. So they mixed roughly ten percent “of a liar seed” into it and shipped it to farmers that way. Which turned out to be: the seed desired dried down to 15% as expected/ but laced throughout the field was ten percent of the crop at roughly 30% moisture. So now: either the farmer pays for an entire elevator load at 30%/ or they hide it, as best they can; and pay nothing for drying at 15%. DO YOU see the problem? Multiplied; because the elevator did not have heat sensors in that new bin; so they could not know.

The elevator being unaware of the trouble; filled a new million bushel bin/ and then found it spoiled. So they mixed it to 3% “foreign material”/ and shipped it out that way; by getting grain from every rural elevator around: to keep from going broke. Which means when it got to the shipping terminal for overseas sales: that ship went out with bad grain/ and it became worse before it docked and unloaded. WHERE PEOPLE no longer wanted an entire ship load of this stuff. So they say: “NO more from there”. And so on, because other problems have arose from the seed companies as well.

It is again noted, that excessive field drainage: robs the aquifer of recharge. Ethanol, destroys the aquifer itself; because once drained: it can collapse. The water here has changed over the last sixty years of chemical usage; from perfect, to now undrinkable; unless desperate; because it does add up, and cannot be undone. But hey you don’t need no damn water now do you; after all “hasn’t happened yet”/ is quickly turning into “yes in YOUR lifetime”. Oh well, too bad; right!

The ground has changed: hard instead of soft (salt damage; herbicides are “salt”), no worms (ammonia damage), no bugs (pesticide damage), few birds (who need insects to eat), very little wildlife. Drainage bridge changes have eliminate ponds; which are the incubation sites for new fish life, and thereby feeding other critters as well. No road kill anymore, a green desert. Soon to be a completely silent spring, for real. And all the people say: we don’t want that anyway; who cares. But no new fish to replenish the stream, lakes, rivers; no new life in all the things which depend upon them; the ending of a chain of life/ by your choices.

The sterilization of all plants, so that only the seed companies control your entire plant food supply/ the end of livestock, as one single epidemic of disease, can now wipe out an entire species (with geneticists working to mutilate everything in nature as fast as possible; “to prove evolution”)/ plant species removed of all defenses, as is corn; with only one strain used for the “mother plant”; so they can control it, without diversity. PUTTING EVERY species of grass at disease risk; including rice, wheat, oats, and more. That corn “mother strain” struggling just to survive/ because they want “same/ same/ same”. While in fertilizers; a new source of potash will keep that going for awhile/ the end of phosphate’s are near. What will you do when that is gone; no efforts made? Over use of ammonia products for nitrogen production/ has been killing the entire ocean coasts of its life. Every incubator of life in the ocean dying/ only plastic to eat. Excessive irrigation and production of ethanol will soon return the dust bowl; without a solution/ as you made no preparations of any kind. Once the aquifer is dead/ the people have to move; livestock and plants will not grow or survive without water; and neither will people. Fossil fuel usage has changed the earth, and you know it: resulting in massive alterations of what can be expected. One earthquake, and the aquifers mix with all the TRILLIONS OF TONS, of poisons you have distributed upon this earth. The end of pollinators. The end of chains of life, as are being destroyed. genetic mutilation of seeds: which eliminates the ability of that life form and all its subsidiaries; open to pandemic collapse. Seed sterilization which will end life on earth. The end of ocean life as is on the brink; no matter what your TV says. The end of habitat/ end of trees/ end of life; extinction of species. All because humanity just didn’t care enough/ didn’t share enough; all saying/ all screaming; “not in my lifetime”; let the children pay. And more.

as all of “university knows, and media” shouts: DON’T LISTEN TO NO DAMN REALITY/ “just tiptoe through the tulips with me”. and don’t forget to FEAR covid/ and BELIEVE EVERYTHING the universities say; as you all know, “you must” obey the university gods.

the grain elevator 1.5 miles away; seems to have gotten itself a new fan (one they run all year long)/ which is producing a frequency I cannot substantially tolerate. Which means, I may be forced to move; because of choices they have made/ realities of manufacturing without a right. The business has no ears, no consideration for me; I have no value to them. But, the courts are owned by the powerful, and there is no justice beyond whatever the powerful want/ no constitution unless the nation is watching; and then only as long as you do. The consequence: I now consider moving from America; to any other place in the world/ because there is no purpose in rebuilding, where chaos will soon erupt like a volcano. doesn’t mean they are better. simply somewhere the CULT of university is god worshipers; isn’t as if SATAN himself was in charge. The universities stole a nation; discarding every life but their own; and like all thieves, they will not be surrendering it: without traps, and deliberate lynch mob creation. after all they have been building an army with bribes for over a decade/ demeaning white america (primary builders/ primary owners), with every media presentation they can make. “and don’t worry”, they have already planned for your guns; and will take all the ammunitions away, or corrupt it, to ruin your guns: which leaves fire, bombs, and other levels of terrorism that will be employed. after all: when counterfeiting your money, and stealing your property and jobs are not enough: war is the perfect solution for genocide. did not the invaders of this Indian nation, NOT do the same? just like every other nation on earth: LETS STEAL, what we do not have/ killing is easy if by surprise! “hurrah for that”/ oh no: food, water, housing; “its all gone, as is the future”. alas “too bad”; but don’t worry though, the universities have a plan: more, biological weapons worse than covid.

I will suggest, “this is not a good sign, for america”/ as my presence here; has been dedicated to; survival of this world. If I move, to another land; I will abandon you forever. But don’t you worry now; Because the only thing the prey learn, from an attacker is to panic sooner, and trust nothing. While the predator however learns, to be ever more stealthy, and less visible, so it can attack with more violence; and consume. “lunch is served”/ here, “have another covid”. after all: the herd (we can’t all be wrong) is always, “an animal”.