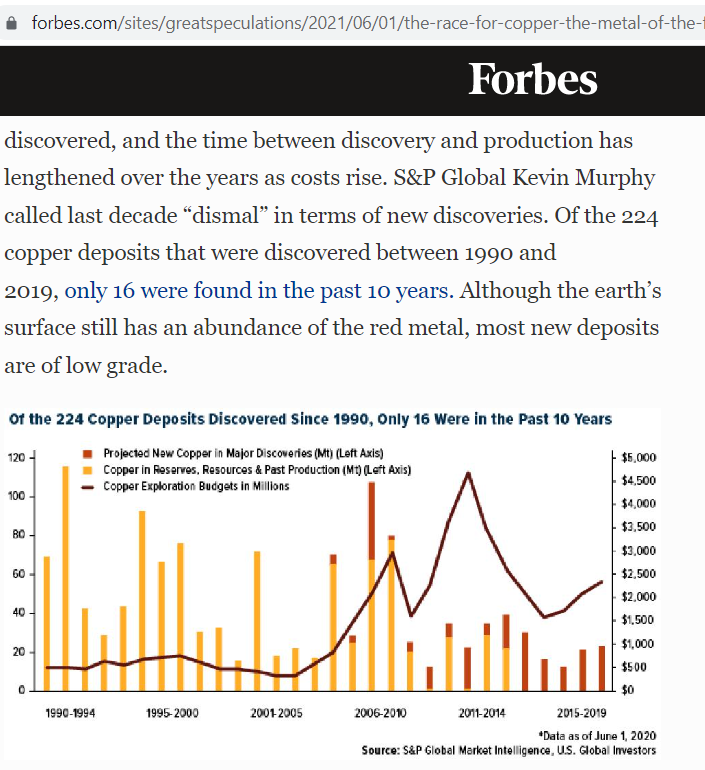

Electric vehicles will not be your saviors; what you save in fuel, will be spent to by a new battery/ while copper is essential in building the cars, it is also essential in every form of “green energy project”/ and your charging stations: real world production is limited and ending.

In this America, the constant disgrace is: those with a university degree believe they are your saviors/ your superiors/ your leaders/ your everything. As a consequence to their pride, they manipulate, control, tempt, alter, change, steal, cheat, betray, terrorize to insure fear, counterfeit because fantasy is all they can offer, become deluded with the claim they and their universities can play god; etcetera. But failure is all they offer, tragedy and mayhem is all they create, horror and war the end result of their decisions/ as consequences mount into confrontations that have no simple solution. The herd then screams: WE WANT WHAT WE WANT/ and the predators controlling them quickly show their fangs, and attack; as is the constant of “the hitler (let them die)/ nazi (we are gods now/ they cannot stop us; the power is ours) parade”. But death is all they offer, only this is for a dying world, only truth, by its own reality can save. Your want, pride, and claim of power is crucified: dead as you are/ or released to extinction instead of you.

REALITY ALIGNS WITH TRUTH, AND TRUTH CREATES PEACE AND HARMONY BY LAW: NOT manipulation, propaganda, lies, stealing, betrayal, terrorism, or other. A description that no university, or its puppets in leadership understand; as they all choose delusion instead of truth.

Today with endless trillions of currency in circulation, [US debt clock: roughly 2 million dollars, per citizen divided equally; babies and all. Proving debts will only be paid by the slaves], all of it, hidden by the wall of electronic money that is not seen as a fact of our lives; by using media propagation of lies “no inflation here. They have lost control as is inflation which cannot be hidden. A reality that is not deterred by slight rises in interest; because more means strife. BUT the rise in fuel prices WILL cool an economy; which means (NO YOU CAN’T demand something for your money/ we DON’T have enough resources; the game is dead/ you must stop). Because the rich man wants MORE. But reality itself proves: the resources are in fact ending/ and the end result of that is life will die; as truth takes control. But thugs don’t care/ liars won’t care/ thieves are too busy to care even if they could/ traitors plot, and terrorists hurry so as not to be deterred.

Rising fuel costs mean: LET THE SLAVE PAY, because the rich have enough numbers not to care. Rising fuel costs push society to buy electric vehicles; because your saviors believe anything they are told/ as is the cost of being a cult. But every kilowatt for vehicles is produced by the least efficient method of electrical generation/ and that means; even in greenhouse gases you gain nothing. But what they don’t tell you as well is: IT IS THE HEAT YOUR RELEASE that causes global warming and all its consequences. Greenhouse gas refers to the atmosphere is not releasing all the heat into outer space, like we believe we want. But of course if it did, that too would be terrifying. As with trains: steam power is far less efficient, burning far more fuel, and produces far more heat; than diesel direct power engines/ so there are no more steam engines. EXCEPT in electrical generation. Failure says: natural gas is the answer/ BUT it uses 5 times as much oxygen as does coal; in a world that releases oxygen/ but does not make it. While the upper atmosphere has been losing oxygen concentration for years now/ as with ozone; but who cares about radiation right. as every new vehicle comes spewing radiation constantly “with its sensors: to protect you”. How grand is that?

No reason to worry, after all: an economy car uses the same amount of oxygen for every highway hour; that 34 people need in 24 hours/ or a semi truck; uses the same amount in that hour of roughly 124 people in 24 hours. And after all: the standard power plant burner, is just the size of an apartment building; so how much oxygen could it really use; right/ hell, who cares anyway, right?

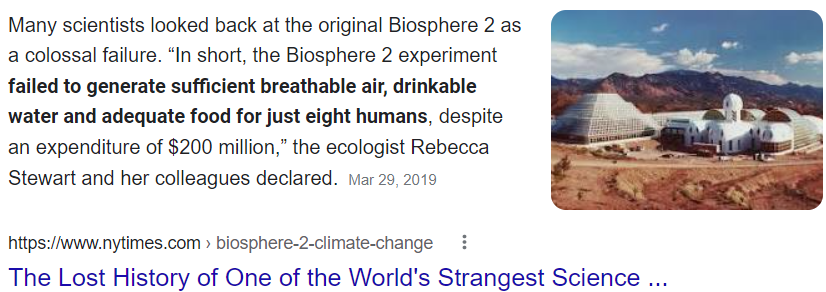

7 million cubic feet under glass; and the only contingency they did not consider was running out of oxygen: in two months. ending the claim “we go to other planets”. NOW: CONSIDER the consequences, for YOUR WORLD! REALITY CONSTRICTS YOU: TO A REAL WORLD INVESTIGATATION OF THE COSTS AND CONSEQUENCES OF EVERY DECISION THAT YOU MAKE, as humanity on this earth. Because you have gone too far, to play the game of death; the universities taught you to play. Today TRUTH DECIDES, or you go extinct. Learn to be human, instead of animal; and you will know that is true.

DO BETTER. DEMAND WORLD COURT! TAKE AWAY THE POWER OF LEADERS AND PROPAGANDA THROUGH MEDIA. IDENTIFY OUR LAW, is our government; AS WE THE PEOPLE CHOSE/ NOT as the insurgents have raged against us. TAKE AWAY THE PRIDE OF PLAYING god/ WITH TRUTH: DEMAND REALITY, PROVE what can be proven. DISCARD obedience to your cult of university knows. AND LEARN WHAT IS TRUE, AND THE COST OF BEING WRONG. CHOOSE A FUTURE YOU CAN SURVIVE. NOT, the curse of this one; which ends in extinction: for earth. and remember: the universities WAR with you, by denying access/ removing and betraying justice, by simply locking the courthouse door, refusing to acknowledge constitutional law; and telling you to wait “forever”. Using media, to push you (the university is god; they cannot be questioned), manipulate you (you have no rights; the universities can destroy nature or do anything they want; they are gods), incarcerate you with lies (there is no inflation; just endless death and asset claims without reality attached), and avoid truth by sending you “experts: (just laugh and play; you don’t know nothing we, your saviors; don’t tell you to believe)” instead of reality.

And yet: they are only former classmates/ none of whom “were gods”. NOT “government” either, as they are just employees! law governs/ unless money corrupts.

The animal wants more/ the animal joins the herd and follows for protection/ the animal fights for pride, as if life was a game/ the animal needs power, to prove I WON/ and YOU lost. The cult exists as a herd, who does not question its leaders; believing they are “the best we can be”. But your reality ends with EVERY RESOURCE IS GONE/ and this world, all its life, and all its habitat, and all its ability to remain at peace: has been destroyed. Because that, is literally WHERE YOUR LEADERS chose to go/ as the HERD SCREAMED, “we won’t pay/ ROB THE CHILDREN instead.” DESTROY their future, DESTROY THIS WHOLE WORLD; so we have more. Trophies, toys, and trinkets: to prove by your garbage mountains; how truly vile you were.

The fundamentals of wind speed controls, whether electronic or mechanical are common and ordinary/ as are the various methods of raising and lowering curtains for controlling the wind/ guides and so on; do not constitute a value called invention. Centrifugal fans which are closed centers/ open centers/ or fixed with funneling effects to direct wind into the center of the fan, or around the fan itself, and methods of changing these as directional funnels are all known; including such things as a fan housing. Lifting winches, automatic catches, transmissions, clutches, warning lights, gps; and so on: are all also obvious, and need not be mentioned. they are known/ not inventions. These effects which are commonly in use such as rudders, and wireless controls, are all known, regardless of the construction and integration into this unit. Not an invention. methods for doing more while functioning in the ocean; such as weather stations/ are also common and ordinary additions.

Primary elements are: these are more suited to independent power generation/ rather than public. However much surface area will be in contact with the wind, decides how much power can be collected? When looking at the wind turbines, the only contact area being driven by wind is the surface of blades: NOT the entire sweep of the propeller. Critical to use as a land generator is weight/ or funneling methods. Critical to the reduction of weight; in larger generation methods is the “merry go round” (do to the lack of directional control in wind). NOT ONLY are several of the individual centrifugal fans placed on the platform to generate their own electricity. The entire “merry go round” platform supporting them will be forced to turn: by adding resistance as is a GENERATOR turned by the platform: which then also becomes an independent generator force. The available wind energy can then be multiplied. Suitable tracks and supporting wheels on the outer edge, to control the weight shifting is obvious. These placed in a x pattern by using several in combination; funnels the wind. Various directional methods of aiding wind direction, thereby focus; incorporated onto the platform, will aid efficiency. Instead of a generator hooked to or for the platform; the energy gained could be used as a pumping method to lift weight of various kinds, to a height suitable for electrical generation when the weight is allowed to fall/ at a later time, when the wind does not flow strong enough.

A cone shaped centrifugal fan, or multi-tiered (wedding cake) fan configuration; which then gains height; also provides a more stationary base for fan construction by shifting the axis turning point; to a more “stable, length versus width is equal”. This allows for a center line holding column, which then, with bracing supports several; in an x pattern/ or three in use arrangement.

the extension in height can also be doubled: by turning one “wedding cake design on top/ and adding to it; one upside down wedding cake fan to the configuration: doubling the size in the same location.

Those shapes can either be bottoms connecting/ or tops connecting; with the addition of a center area protrusion to collect the focused wind [an hour glass, with a fan style plate in the middle so to speak].

all are claimed for public ownership, and international dispersion April 21, 2022 8:00am

IF YOU MAKE THEM VERY LARGE: to control wind speed; you must disconnect from direct electrical generation/ to incorporate water pumping: thereby an easily manipulated fan control, regardless of wind speed. The wind fan turns the pump, moving water into a suitable container/ which is then released back down into an electrical generator, at an easily controlled rpm. Or it can raise and lower weights of any other sort, which are then released in a controlled manner to produce a constant rpm in the generator. Other methods are complex, and far less reliable. Putting containers on top of earthen mounds is an easy way of supporting them/ while these mounds can be used for funneling and focusing the wind. They will also be used as anchor points for cabling control over the central axis of the “wind spinner”.

On these very large machines; you will be using a closed center fan surface. Which allows for directional control of wind pushing the blades into a focusing port at the back end of the blade: collecting energy by directing what would otherwise be pushed outside the vane, and around the fan: into the interior instead. This directional focused force; can then be used on a secondary spinner within the structure; to capture as is; generate a secondary supply of energy within the same structure. Several are used in stages within the appropriate chambers already there.

These function as independent units of power generation; thereby these are sectioned fans; which spin around the center pivot point, and either generate electricity at each spinner; combining onto a common collection brush to exit the machine as electricity. OR by the use of gearing the spinners turn a shaft which is either independent for electrical generation/ or combined by gearing at top or bottom; into the overall torque of the machine as a whole.

Because these are long term installations; a “bowl cap” could be used to direct additional wind forces into the capture area/ and could even participate as a high water capture point. The central axis support, creates the drain, down to electrical generation.

. Floor sections of a high rise building in cities can be used for centrifugal wind generation of electricity: by taking control over/ one or two elevator sections. One is raised, while the other is dropped for electrical generation. To raise and lower a centrally located weight/ which is then dropped for mechanical generation of steady flow electricity. Batteries can also be used/ but these do not last “forever”. If you pump water/ that water up and down will be more efficient/ but you have to control and support the weight (which can be done by simply draining the water in advance) even during major wind events; and water flow will create noise.

IF you wish to try direct electrical generation in buildings: it is necessary to use “hinged drop down, and/or; up wall sections” to control the wind speed. Several wind spinners can be controlled all at once by that method; if they are geared together [as independent, wall lines]; it becomes far less of a problem to maintain the necessary manipulations of electricity being created.

if you wish to try: wind propulsion to move vehicles, is entirely possible; with any usable wind. directly tied to the drive train or as an electrical generator to run a motor that then drives the vehicle. simply mount it on the vehicle/ or make an addition to add on to the wind spinner; that allows for passenger or materials to be hauled. one of the few uses for “unaided driverless” vehicles; as time, versus speed; is not going to be great. But patience needs little else.

By using a cliff or a ground swell or a focusing ground effect: instead of vertical centrifugal wind spinners/ you can lay them out as horizontal, or on an incline ; thereby limiting some costs. The fundamental most likely to produce the desired results however are: the production of area lakes that can be used for the water supply/ and a suitable mountain or rise; for pumping the water up/ and generating electricity as water is focused into water propulsion electrical generators. Thereby returning to the lake, to repeat the process of mechanical wind solutions.

Horizontal means; limited to wind direction/ or must be mounted on a circular track.

As to the realities of plastic in the oceans and more: the bio-degradable plastics produce more tiny particles much faster, than the older plastic/ thereby intensifying the problem. And putting “nano-size” piece of plastic; in living life quicker. Contributing to the ‘”grey-goo” of nano technologies invading all forms of life. Plugging cellular machinery, with parts and pieces which cannot be removed: Armageddon (nature in chaos) comes quickly now.

On barges; tiny particles might be separated with electricity/ or perhaps forcing bubbles up through the water (studying it to see where they go)/ using a “slap board” within the containers that moves back and forth with the waves; to release the plastic from water molecules. Or whatever method will work; wind generated power has potential.

Centrifugal is not likely to work; but worth a try.

And then there are the millions of tons of pharmaceuticals dumped in the water/ because none will take them back; flushed away into the rivers. Along with a trillion tons of agricultural, lawn chemicals, industrial chemicals and more; but hey who needs water? Who needs a base food group like insects; it just means no more birds, and “a million more, lost forever”. But who cares, right?

and then there are the terrorists igniting forest fire to “take it all away, with hate”. Ethanol, to remove every glass of drinking water needed in the future; and a billion more “university knows everything decisions”.

-

But using anchored ocean born wind turbines to pull cold water from the depths and support coral reefs: is clearly a benefit; that works for life and ocean with very little input.

- the video, partway down on the homepage “wind solution machine/ wind power for ships, boats etc. for pulling plastic out of the ocean” is; likely, being targeted for theft. it starts in the middle, and has the alternate bone solution at its start. if you make it go back/ then it seems to start at the beginning.

an addition to the bone solution method; depicted by video; of supporting a broken bone. 4-21-2022 12:30pm is:

When it is a split lengthwise bone: if needed two halves, locked together; by common methods: up movement on one and down movement on the other: set with screws/ or, a locking clamp joint as depicted, in the James Osterbur video release; can be used to establish these will not move.

this requires two sections as described above; clamped together four pieces with one lock: placed into machined grooves to form a single solution. This is the one healing section defined by two halves to each top and bottom section of bone clamp/ with a lock to hold them together. That can be better than one/ or not.

-

In the real world of broken bones: we use a, individual fully enclosed pipe, sliding the bones inside each of the bone pieces to be reunited. THEN, using the above lock, along with channel forms machined grooved into the pipes, to sustain position; of both pieces and the lock. These joins all three those pieces into one healing section.

-

Each piping section whether whole or halves, will be tapered on the ends/ with a thicker center area; so that machining of grooves can take place. Suitable rounding of every corner is known. Although bones are largely “the very same/ dependent upon size”. There are differences that are largely “common and ordinary” within a few parameters. Therefore a selection of variables would be needed by the doctor mending the bones.

- for the sake of it: no “forest park” should be without an audible siren located along the path; that goes off once a day at whatever time you like. they should sound off, “with one short blast for north/ 2 for west/ and so on” for referencing position. solar powered and placed miles apart/ you can use them for depositories or communications; in case of emergency. its cheaper, than search and rescue. Its simple/ why not.

- along the same lines: deviant sexual behaviors in males; are the result of chemical addiction with what the testicles produce. It is well documented “women have their own tool, for producing whatever chemical response sex does for them. produce a tool for men, and most of the deviant sexual behaviors, including most rape; should disappear. While nature should never be fooled with; “same for men/ same for women”; is fair.

-